The post The role of reuse in industrial water needs appeared first on The Source.

]]>The recycling of industrial wastewater is increasingly important to address water security, improve the environment, and capture resources that may otherwise be lost through discharges. Hence there is a move for more industrial sites to recycle and reuse water with this requiring appropriate treatment. The quantities and quality of water involved differ greatly depending on the industrial process concerned, along with the great variety of contaminants which require treatment. High-tech industries in particular may require ultrapure water, demanding more extensive and challenging processes.

Thirsty industries

When industrial sites are built in areas of high population density, in the vicinity of a mega city for example, regions can experience competing demands for water from industry, agriculture, and domestic use, placing pressure on resources and the environment.

Industrial processes require large quantities of water for cleaning, cooling, and emulsions, in addition to being used as a carrier fluid for processing systems.

The hidden water consumed by industrial processes can be surprising. The production of a single cotton T-shirt consumes 2500 litres of water (Singh et al., 2023); the production of a kilogramme of paper requires 10-100 litres of water (Esmaeeli et al., 2023); and a litre of beer uses 5-20 litres of water (Götz et al., 2014).

Furthermore, industrial wastewater contains various contaminants that are generated or leached from production lines, including additives, final products, solvents, salts, and more, which must be treated to meet discharge criteria.

Recalcitrant emerging contaminants

Industrial production relies on an array of chemicals, including per- and polyfluoroalkyl substances (PFAS), commonly known as ‘forever chemicals’. As a consequency of industrial processes and agricultural production, pharmaceuticals and endocrine-disrupting substances can also threaten the environment.

In addition, brine wastewater can be formed in industrial production lines and as a result of membrane processes such as reverse osmosis. In many cases, it can contain high levels of recalcitrant organics, which can negatively influence the performance of desalination processes, as well as the crystallisation and purity of recovered salts.

Certain industries can produce particularly high concentrations of contaminants in wastewater, with material synthesis, food processing, and dyes and paints sometimes producing wastewater with concentrations as high as in the tens of thousands of mg/l of chemical oxygen demand (COD), and thousands of mg/l of total nitrogen (TN) and salts.

Sustainability toolbox

To tackle competition over water resources and reduce discharges of industrial contaminants into the local environment, many countries and regions use a ‘toolbox’ of solutions to improve the sustainability of industrial water use, including tiered pricing, water auditing, and green labelling.

Many water treatment processes such as aeration, membrane separation, and evaporation are energy intensive. To reduce energy use, energy must be optimised at the level of the whole process. In addition, excessive heat and pressure in production lines can be integrated into water treatment processes. To achieve energy optimisation, synergies are required between R&D teams to improve the efficiency of water management processes and – more widely – collaboration between researchers, engineers, and institutions and enterprises is required.

Water reuse

Wastewater recycling is also an important tool for increasing water use efficiency and has proved to be viable in many applications across a broad range of industrial sectors, including those where water quality is important.

One example of successful reuse is in breweries, where it has been found that the volume of water required for producing one litre of beer can be reduced from 20 litres to two litres by integrating a water reuse process into the water system (Götz et al., 2014).

The benefits of water reuse include that less industrial effluent is discharged, more wastewater is recycled, and water security is improved, which is especially important in regions where water scarcity is a concern. We are even now seeing the construction of zero-liquid-discharge plants.

Membrane fouling and scaling

Membrane technology is key to many wastewater reuse processes. The high concentration and complexity of contaminants in industrial wastewater can easily cause membrane fouling and scaling, necessitating that sufficient pretreatment be deployed based on the nature of the wastewater to be treated.

Smart management

It is important to take into account the fact that industrial production often depends on market demand and supply chains. As a result, the composition and volume of wastewater can fluctuate dramatically, especially where several production lines are deployed. In addition, the water quality and quantity requirements of a process may also change frequently. To manage these fluctuations a smart management system is required to efficiently respond to production requirements across all treatment units in a system.

High tech industries

Different water quality criteria are defined for different industrial water uses. Some applications do not require water of a very high quality – irrigation and floor cleaning, for example. However, some sectors – high tech sectors in particular – may require extremely high-quality ultrapure water.

“Countries and regions use a ‘toolbox’ of solutions to improve the sustainability of industrial water use”

The European Pharmacopoeia categorises water quality for pharmaceutical production into two grades with differing Total Organic Carbon (TOC) concentrations: purified water (TOC <500 μg/l, conductivity ≤4.3 μS cm–1), and water for injection (TOC <500 μg/l, conductivity ≤1.1 μS cm–1) (Rögener., 2024).

The production of semiconductors requires ultrapure water (TOC <3 μg/l, conductivity 0.055 μS cm–1), necessitating critical steps including wafer rinsing, the preparation of chemical solutions, and photolithography immersion, with an average water consumption of approximately 8.22 l/cm2 (Wang et al., 2023).

Computer services

Data storage centres consume a lot of water, directly for cooling and indirectly through electricity consumption. It is projected that per capita water use for data handling will be 1100 litres in Europe in 2030, 3.8 times higher than the value in 2020 (Farfan et al., 2023), emphasising how important water security is for the technology systems that the world now relies on.

Given the importance of industrial wastewater reuse and the strong demand for innovative solutions, IWA will be holding a ‘Water in Industry’ conference

in Nanjing, China, on 23-27 September to provide a communication platform for both researchers and practitioners. This is planned to develop into a series

of events to encourage synergies to be established, collaboration kindled and innovative solutions to be incubated. •

References

- B.J. Singh, A. Chakraborty, R. Sehgal, ‘A systematic review of industrial wastewater management: Evaluating challenges and enablers’, J. Envrion. Manage., 348 (2023) 119230. https://doi.org/10.1016/j.jenvman.2023.119230

- A. Esmaeeli, M.-H. Sarrafzadeh, S. Zeighami, M. Kalantar, S.G. Bariki, A. Fallahi, H. Asgharnejad, S.-B. Ghaffari, ‘A Comprehensive Review on Pulp and Paper Industries Wastewater Treatment Advances’, Ind. Eng. Chem. Res., 62 (2023) 8119-8145. https://doi.org/10.1021/acs.iecr.2c04393

- G. Götz, S.U. Geissen, A. Ahrens, S. Reimann, ‘Adjustment of the wastewater matrix for optimization of membrane systems applied for water reuse in breweries’, J. Membr. Sci., 465 (2014) 68-77. https://doi.org/10.1016/j.memsci.2014.04.014

- F. Rögener, ‘Increasing the Sustainability of Pharmaceutical Grade Water Production,’ Chem. Ing. Tech., 96 (2024) 522-527. https://doi.org/10.1002/cite.202300152

- Q. Wang, N. Huang, Z. Chen, X. Chen, H. Cai, Y. Wu, ‘Environmental data and facts in the semiconductor manufacturing industry: An unexpected high water and energy consumption situation’, Water Cycle, 4 (2023) 47-54. https://doi.org/10.1016/j.watcyc.2023.01.004

- J. Farfan, A. Lohrmann, ‘Gone with the clouds: Estimating the electricity and water footprint of digital data services in Europe’, Energy Conversion and Management, 290 (2023) 117225. https://doi.org/10.1016/j.enconman.2023.117225

The author: Yongjun Zhang is a professor at the School of Environmental Science and Engineering, Nanjing Tech University, China, and executive conference chair of ‘Water in Industry’ 2024

Water in Industry 2024

The Water in Industry Conference 2024 will be held at the Yangzi River International Conference Center, Nanjing on 23-27 September.

Topics will include: zero liquid discharge; resource recovery; removal of recalcitrants and metals; pre-membrane treatment; cooling water; water energy nexus; and best practice examples.

More information

To find out more about ‘Water in Industry’ 2024 and register to attend,

visit https://www.iwa-win.org/

The post The role of reuse in industrial water needs appeared first on The Source.

]]>The post Corporate sustainability net positive water goal for Intel appeared first on The Source.

]]>Other corporate sustainability aims are to move entirely to ‘green’ power and to achieve zero waste to landfills across the company’s global manufacturing operations, as well as doubling the number of women and underrepresented minorities in senior leadership roles and scaling the impact of its supply chain human rights programmes.

Manufacturing semiconductors is a water-intensive process – ultrapure water is used to remove impurities from the silicon wafers, and industrial and reclaimed water is used in Intel’s manufacturing plant systems.

According to the company, it has spent 20 years refining its water use and it says it has been able to restore about 80% of its original water use to the community. The focus now is on achieving 100% restoration.

The company says it funds collaborative projects to support local watersheds, with the aim of restoring water in amounts equal to the water it uses to close the gap in its water balance. According to Intel, these projects are either focused on agriculture, conservation, or in-stream flow protection, and they support communities, the economy, and the environment and address local water issues.

To date, Intel says it has funded projects that will restore an estimated 1.8 billion gallons per year (BGY) of water when complete. Of these, 11 projects were finalised by the end of 2019 and 1 BGY of water was restored in 2018 and 2019 together. The company has pledged to evaluate and adjust its volumetric target annually, because its future water consumption may change.

Locations of the 24 water restoration projects funded so far include Arizona, California, New Mexico, and Oregon in the US, and in Bangalore, in India. The company is building a massive new water recycling plant in Hillsboro, Oregon, which will be able to recycle 1 billion gallons of water a year when complete in 2021.

The post Corporate sustainability net positive water goal for Intel appeared first on The Source.

]]>The post Containerised industrial effluent solution for UAE appeared first on The Source.

]]>The 300m3/day plant features six containerised treatment units, as well as 14 of the company’s W-Tank bolted storage tanks for wastewater treatment and clean water storage. The W-Tank is made of GRP. According to the company, the solution fitted the need for the plant to be able to cope with extreme climate and the corrosive nature of the effluent. The COD can reach 45,000mg/l, while the average conductivity is 20,000 μS/cm.

The complete project included two containerised Anaconda flotation systems, the Anaconda FRC-20, which include three dissolved air flotation units. Toro supplied a containerised plant for sludge dewatering, including use of an FPA120/25 Draco automatic filter press. The other three containerised units house a chemical dosing system, a final filtration stage, and the plant’s blowers.

According to Toro, pre-assembly in containers facilitated installation and completion of the project.

The post Containerised industrial effluent solution for UAE appeared first on The Source.

]]>The post Phosphorus recovery and reuse from wastewater appeared first on The Source.

]]>Phosphorus (P) is essential to human life and vital for food production. It is the critical building block of DNA, cell membrane and bones and plays a crucial role in cellular energy metabolism. Today, P is mostly obtained from mined phosphate (Pi) rock, but natural reserves of Pi rock are concentrated in a limited number of countries such as Morocco, China, and the US. On the other hand, an inefficient use of P and the leakage of phosphate-containing fertilisers, detergents and sewage into water bodies are causing irreversible eutrophication problems. Moreover, mined Pi rock is largely contaminated with toxic heavy metals such as cadmium and radioactive uranium. From health and environmental perspectives, there are increasing concerns about the long-term application of chemical fertilizer to farmland.

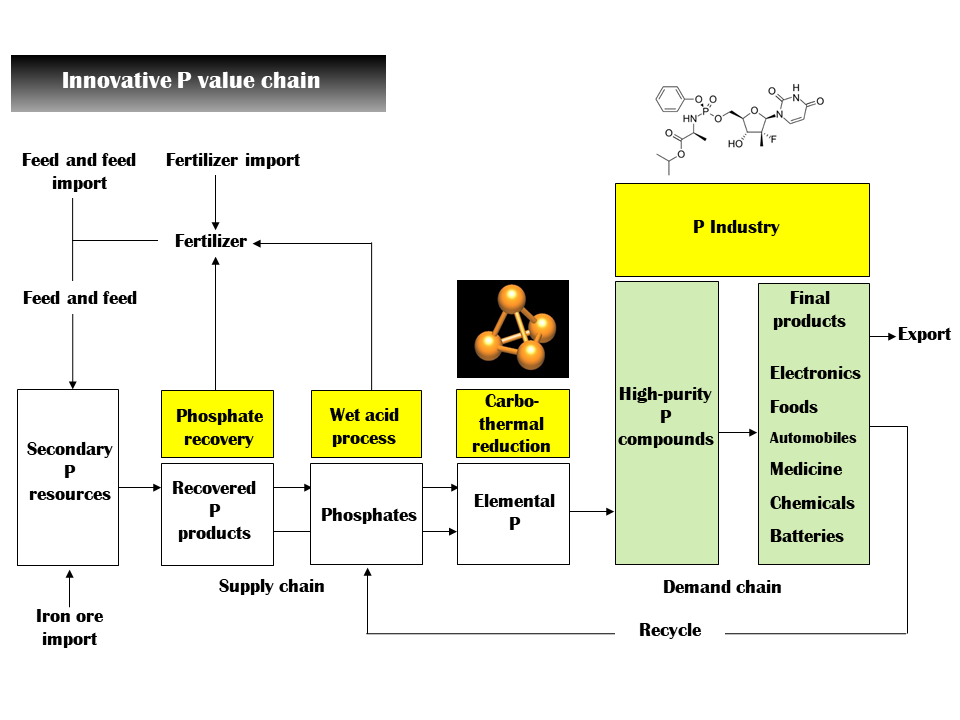

Increasing attention has been paid to the development of P refinery technology that can recover P from waste streams and reuse recovered P products for agricultural and industrial purposes. In the wastewater treatment sector, P is removed from wastewater using chemical or bio-based technologies. Removed P ends up in sewage sludge which is then subjected to anaerobic digestion, dewatering and incineration. This offers hot spots for P recovery from (i) the rejected water from sludge dewatering, (ii) digested sludge, (iii) and incinerated sludge ash.

More than 70 full-scale P recovery plants are currently operating in Europe, North America, and East Asia. Basically, the P recovery technologies are (i) chemical Pi leaching from incinerated sludge ash, (ii) Pi salts precipitation, and (iii) struvite crystallization after anaerobic sludge digestion. Incinerated sludge ash having the high content of P is also used as a raw material for the manufacture of phosphoric acid in a wet acid process.

P recovery practices are now expanding not only to the wastewater treatment sector but also to the manufacturing sector. In the manufacturing sector, Pi must be removed from wastewater to meet stringent effluent regulation in areas vulnerable to eutrophication. The recycling of recovered P products as a fertilizing material can save the costs of sludge disposal and leads to the significant reduction of plant operating expenses. P recovery is also practiced from solid waste streams such as animal manure and steelmaking slag. In East Asian countries, including China, Korea and Japan, steelmaking slag is one of the most important secondary P resources. Recovering P from steelmaking slag allows the rest to be reused as raw materials in blast furnaces. This has the enormous potential to improve the resource efficiency of steelmaking process.

Except some European countries such as Switzerland and Germany, no regulation requires P recover and recycling for the wastewater treatment sector. This allows the wastewater treatment sector to consider P recovery as an extra service. On the other hand, fertilizer companies cannot accept recovered P products unless they bring some economic benefits to their business. P recycling practitioners need to establish stable channels for the distribution and sale of recovered P products. To make P recycling business more attractive, it is critical to develop a new value chain that can extract the maximum value from secondary P resources.

East Asian countries are becoming increasingly the center of high-tech industries in the global economy. They need high-purity P compounds for manufacturing high-value added products including semiconductor, lithium battery, liquid crystal panel, medicine, and fire-retardant plastics. Elemental P, called white or yellow P, is the essential starting material for the manufacture of high-purity P compounds. The secured supply of elemental P is becoming increasingly difficult in the global market. Actually, the supply risk is much higher than that of Pi rock. EU added elemental P to the list of its critical raw materials, taking into account the potential risk of the secured supply of high-purity P compounds in Europe.

Elemental P is now produced by only four countries in the world, including China, USA, Kazafstan, and Vietnam. The production of elemental P is an energy-intensive process which is strongly dependent on locally-sourced electricity, Pi rock, and cheap labor forces. It requires approximately 14 MWh of electricity for each ton of elemental P produced. Moreover, since Pi rock is contaminated with toxic heavy metals and radioactive elements, pollution control is another difficult problem regarding the production of elemental P from Pi rock using a conventional arc process.

To solve these issues, it is necessary to redefine the P value chain through technology and business innovation based on recycling. The technology innovation needs to promote the development of (i) highly-efficient P recovery from secondary resources, (ii) an improved wet acid process to generate phosphoric acid from recovered P products, (iii) an innovative carbothermal reduction of low-grade Pi to elemental P with minimum electricity consumption and low environmental burden, and (iv) new processes for the manufacture of high-value added P compounds to meet the demand from high-tech industries. Among them, the key technology is the innovative carbothermal reduction of low-grade Pi to elemental P. The technology and business innovation based on P recycling, called P Innovation, can make a great contribution not only to the sustainability of agriculture but also to the secured supply of high-purity P compounds to the high-tech industry. There is no significant tradeoff in the use of P between agriculture and industry, because industry needs only a small fraction of recovered P for their business. Rather, redefining the supply chain of high-purity P compounds can offer economic incentives to P recovery from secondary P resources, thereby making a great contribution to the sustainable use of P not only in agriculture but also in industry.

The technology and business innovation based on P recycling, called P Innovation, can make a great contribution not only to the sustainability of agriculture but also to the secured supply of high-purity P compounds to the high-tech industry. There is no significant tradeoff in the use of P between agriculture and industry, because industry needs only a small fraction of recovered P for their business. Rather, redefining the supply chain of high-purity P compounds can offer economic incentives to P recovery from secondary P resources, thereby making a great contribution to the sustainable use of P not only in agriculture but also in industry.

Hisao Ohtake is a Guest Professor of Phosphorus Atlas Research Institute at Waseda University, Tokyo, Japan. He is also a Professor Emeritus of Osaka University, Osaka, Japan. He serves as the Chairman of Phosphorus Recycling Promotion Council of Japan, which is now being reorganized to the Phosphorus Industry Development Organization of Japan. His recent publication is Phosphorus Recovery and Recycling, Springer Nature, 2018.

The post Phosphorus recovery and reuse from wastewater appeared first on The Source.

]]>The post What will be the leading edge water solutions of the 21st century? appeared first on The Source.

]]>Throughout history, securing a reliable and safe water supply, and dealing with wastewater, have been two of the driving forces behind the development of human populations. Entire civilizations have grown and vanished in response to water availability and their environmental impact on water resources. What was true for ancient Babylonians and Maya continues to be true today: water management remains one of the greatest human challenges.

The technologies and science we apply today would be alien to our forebears, but scientists and engineers continue to respond to water challenges through the research and development of new water and wastewater treatment technologies; find new ways to extract value from wastewater through resource recovery; and implement sanitation treatment systems and technologies that improve both human and environmental health.

Addressing these critical issues was central to the recent IWA 15th Leading Edge Conference on Water and Wastewater Technologies in Nanjing, China. It brought together researchers and practitioners who are passionate about exploring and applying leading edge water solutions for the 21st century. This sector-leading event gives new insights into how pioneering science, technological innovation and leading practices are shaping the major transformation in water management that is underway. Amongst the hot topics debated during the meeting, several key emerging trends, likely to disrupt the water sector, were highlighted:

Towards a holistic ‘urban water cycle’ approach

In practice, water professionals have started to rethink and optimize water systems, moving to urban systems that integrate drinking water and wastewater systems for Direct Potable Reuse, tapping conventional water resources, increased use of resource recovery, as well as considering natural-based solutions in urban water management.

Breakthroughs in addressing emerging contaminants

An increased presence of emerging contaminants, such as pharmaceuticals, personal care products or pathogenic microorganisms, not only threaten the quality of water sources and wastewater streams around the world, but challenge the efficiency of current treatment processes. There is mounting urgency to advance research on innovative treatment technologies that can control these emerging contaminants and protect human health. Some promising modern tools and approaches include advanced oxidations, digital information technology, and state-of-the-art molecular genetics tools.

Application of advanced and new materials for water treatment

Looking at the evolution of water and wastewater treatment technologies, the rapid development and application of advanced materials has increased efficiency and decreased costs for water treatment. These include multifunctional membranes, nano technologies, novel catalysts and high capacity absorbents.

Engineering of microbiomes to fight antibiotic resistance

Fascinating developments in the microbial field have seen the application of microbiome engineering become more important for enhancing wastewater treatment and drinking water quality. Microbial control is getting renewed relevance and urgency with the rise of super bugs.

Digital water

Smart technologies are driving efficiencies across sectors, and water is no exception. Smart meters, sensors or real-time control solutions are becoming an indispensable asset for water utilities to improve overall performance. By increasing their ability to operationalize data into practical solutions, such as detecting leaks, utilities are able to reduce water loss and reduce energy consumption.

Tailored solutions to improve water quality and wastewater treatment in the Global South

More attention is now being focused on the improvement of water services and wastewater treatment in countries in the Global South. Small and decentralized water systems are increasingly applied together with onsite solutions (such as Non-Sewered Sanitation), to reach increasing numbers of previously unserved or underserved people.

The IWA’s Leading Edge Technology Conference is an important incubator for accelerating the development and diffusion of new technologies and leading edge practices. As the world faces a future of increased water scarcity, growing demand for water, and more frequent and severe water events such as floods and droughts, our response has to rise to the challenge.

Join us at the 16th IWA Leading Edge Technology Conference to be held in Edinburgh, UK, 10-14 June 2019, and be part of the solution.

Find out more here and visit the LET website for upcoming updates at http://iwa-let.org/

The post What will be the leading edge water solutions of the 21st century? appeared first on The Source.

]]>