The post Advancing action on AMR appeared first on The Source.

]]>For her keynote presentation at the IWA World Water Congress & Exhibition in Toronto, Canada, in August, Professor Amy Pruden, of Virginia Tech, USA, chose a title of ‘The Water Sector and the Slow Pandemic of Antimicrobial Resistance’. It is a title capturing an issue that stems from a natural ability of microbes that brings with it dire warnings.

Pruden sums up antimicrobial resistance, or AMR, as “the ability of microbes to survive antimicrobial treatments”. So, this includes resistance to antibiotics – “one very precious class of antimicrobials that treat bacterial infections”.

“How do they do this? Simply put, it’s in their DNA – their antibiotic resistance genes, or ARGs. These encode the ability of bacteria to do things like pump the antibiotic out of the cell, to break the antibiotic down, or to modify the cell target so that the antibiotic is no longer effective,” explains Pruden.

“Microbes are a lot smarter than we often give them credit for,” she continues. “They are very adept at evolution on very rapid time scales. They can also do something that we humans can’t do – they can physically share their DNA through horizontal gene transfer.” This latter point is relevant for water treatment – killing microbes may not be enough. “We also have to think about their DNA.”

A global health concern

Then come the warnings. One hundred years ago, a simple cut or bout of pneumonia was deadly, and this is not a place to which we would wish to return, comments Pruden. Noting a report in The Lancet and the 2016 UK ‘O’Neill Report’, sponsored by the Wellcome Trust and the UK Department of Health, she says: “They issue a dire warning that the slow pandemic of AMR is here. And if we don’t coordinate globally to do something about it, deaths due to AMR will surpass those due to cancer.

“On a hopeful note, there is global action taking root,” Pruden continues. One key example here is the World Health Organization’s (WHO’s) Global Action Plan on Antimicrobial Resistance, with WHO advocating for a ‘One Health’ approach. This requires all Member States to develop a national action plan for combating antimicrobial resistance. “To date, 164 of these national action plans have been published,” says Pruden.

Other examples she gives include the G7 Health Ministries. “When they met in 2022, they identified three top global public health threats: the COVID-19 pandemic, the slow pandemic of AMR, and climate change,” notes Pruden. The response, supported as part of the G7 Pact for Pandemic Readiness, included “development of integrated, interoperable and interdisciplinary surveillance”, including antimicrobial resistance. Here, Pruden points out: “They specifically call out non-invasive national wastewater surveillance systems.”

The water sector contribution

The global ‘One Health’ response to AMR requires action on multiple fronts and, on this note, Pruden highlights the UN Environment Programme (UNEP) report ‘Bracing for superbugs’. This covers the state of the science, the role of antimicrobial resistance in the environment, and what can be done about it. “I’m proud to be one of the co-authors of this report,” says Pruden.

“One of the take-home consensus messages was that AMR challenges cannot be understood or addressed separately from the triple planetary crisis of climate change, biodiversity, and pollution and waste.

“The report elaborates on the role of antimicrobial resistance in the environment, particularly the water environment. So, water environments are key recipients, conduits and sources of exposure for AMR,” she adds, noting prime examples given as agricultural runoff, industrial inputs, and wastewater inputs.

“It also highlights how, if we are going to use this ‘One Health’ framework – people, animals, environment – that has been adopted by the World Health Organization, we need to get a handle on the understanding of the environmental dimensions of AMR.”

Here, Pruden highlights the relevance of wastewater. For a start, pharmaceuticals are not broken down fully in the body, so pharmaceuticals such as antibiotics are excreted into sewage. Wastewater also contains antibiotic resistant pathogens, antibiotic resistant genes (ARGs), and mobile genetic elements (MGEs) – “pieces of DNA that help ARGs move across bacterial populations”. Meanwhile, treatment processes such as activated sludge – perfected over the past 100 years – select for a particular microbial ecology. “We are concerned that this could be inadvertently creating an environment that’s ideal for selecting for antibiotic resistance, so some refer to this as a possible hot spot for the evolution of AMR.” This is a point Pruden returns to later.

Pruden highlights that the UNEP report also provides a framework for taking action around the environment and AMR, especially around the sectors that produce and use antimicrobials and the wastes they produce. “We need to think about their waste management in terms of AMR. So, do we need to focus on source control? Do we need to focus on requiring that there be pretreatment before discharge to the sewage works?” asks Pruden.

The need for monitoring

“One of the things that the water sector can do right now is help support monitoring of AMR. There are a lot of knowledge gaps in terms of the rates of resistance and where it’s coming from,” she says.

This need was noted in the 2019 launch of the Water Research Foundation (WRF) ‘Project 5052’, the findings of which were summarised in a 2022 Environmental Science & Technology paper, covering research in Switzerland, Hong Kong, India, the Philippines, Sweden, and the USA.

“We spent a good portion of the pandemic wrapping our heads around what we need to do in terms of AMR monitoring in water environments,” says Pruden. “A key takeaway is that where to monitor and what to monitor really depends on the objective of your monitoring programme.”

She points to four aspects around monitoring: monitoring antimicrobial resistant bacteria and genes circulating in human populations; quantifying what is evading treatment; quantifying removal efficiencies; and assessing evolution of new resistance pathogens and mobile ARGs.

“The first one is wastewater-based epidemiology – testing the sewage itself to get a sense of the carriage of AMR organisms in the population served. The second is to look at the effluents coming out of these plants and to see if there are any AMR constituents of clinical concern. The third is to look at the treatment processes, quantify removal rates and identify which are the most effective at attenuating AMR. Finally, the fourth is the issue of hot spots: are there places in the environment where there’s a convergence of factors, where there’s an elevated probability of resistant pathogens evolving?”

Techniques for testing

In terms of testing techniques, Pruden says: “AMR is tricky… It is a multi-headed beast. So, there’s really hundreds of strains of bacteria that can be resistant, and thousands of ARGs, so we concluded that really all the methods have value. Again, it depends on what your objectives are.”

She notes that use of cultures is always going to be of value: “It’s the one method that can confirm a viable organism.” Here, she refers to WHO’s Tricycle Protocol. Non-culture-based techniques include those built around polymerase chain reaction (PCR). “Then, most recently, a real game changer has been DNA sequencing… We can use non-targeted DNA sequencing to profile everything that’s in there and just compare with databases to see what we’re interested in.”

“Recently, we were able to demonstrate the potential of this metagenomic DNA sequencing approach. We sent students around the world and sampled sewage from representative wastewater treatment plants. It was really remarkable how we could distinguish these sewages based on their ARG content,” says Pruden.

“What we saw was that the wastewater from Sweden had the lowest abundances of ARGs of anywhere that we tested. This makes sense because they’ve been one of the most proactive countries in terms of adopting policy to combat the spread of AMR, including banning antibiotic use in livestock since the late 1990s.

“We also saw that the highest levels of ARGs in sewage were in parts of the world that have very high population densities and that don’t require a prescription from a doctor to use antibiotics,” she adds.

“There’s a lot of potential here, not only to fill the gap in terms of clinical testing and understanding the rates of antibiotic resistance carried in human populations, but also to inform effective global policy – what works in terms of stemming the spread of antimicrobial resistance.”

Here, Pruden returns to the question of whether wastewater treatment plants are hot spots for AMR. “We went to those same wastewater treatment plants, and we sequenced the metagenomes of the activated sludge. The ARGs were sharply depleted in the activated sludge. This is quite encouraging, that wastewater treatment plants can be a barrier to the proliferation of ARGs.”

This was explored further using long-read DNA sequencing. “We concluded that the microbial ecology of activated sludge is a natural barrier to the proliferation of ARGs.”

“That’s not the full story,” adds Pruden, who says that current work is looking at which ARGs escape treatment and which are transferred horizontally. Bench-scale testing involved using blends of municipal sewage and hospital sewage, and it was possible to track increases in ARGs that related to the same classes of antibiotics increasing in the sewage. This work was published recently in Nature Communications.

The benefits of monitoring

There is a wider dimension to this wastewater monitoring. “We talk about the need for a One Health framework to combat the spread of AMR globally, but the environmental dimension of that One Health framework is really not up to speed with the level of knowledge of the others. This kind of monitoring can also help us to identify epidemiological links between the environment, humans and animals; then we can focus on those areas of transmission. We really need these large, comparable, longitudinal datasets to identify the drivers of AMR.”

Other areas include the need to inform risk assessment around regulatory limits, and to identify hot spots for the evolution and spread of AMR. “That way, we can focus our resources there, and we can identify treatment technologies that most effectively mitigate AMR,” says Pruden. There is also the potential to inform human and animal medicines regulation about which antibiotics will be most effective at population scales. Imagining doctors being able to check in real time on a mobile phone app, Pruden comments: “This last one is kind of a dream of mine.”

Picking up on the UNEP report, Pruden highlights areas where the water sector can contribute to progress, including continuing to design and operate treatment processes that produce excellent water quality. “These will surely also benefit AMR,” she says. Another is to work to identify which processes are most effective at removing antimicrobials, resistant bacteria, ARGs and mobile genetic elements (MGEs), and ones that do not increase these constituents. Another is the potential for source control, including at locations such as hospitals and pharmaceutical manufacturing facilities. Another is to look at the needs of locations currently without appropriate waste treatment. “Sadly, it is often the low- and middle-income countries that bear the burden of AMR,” adds Pruden.

She emphasises that there is a global, coordinated effort under way around AMR, so the sector is not alone. There are also wider opportunities to seek partners and co-benefits in relation to other contaminants of emerging concern.

Addressing the audience in Toronto, Pruden was also pleased to highlight that she is part of a team selected for a new US Environmental Protection Agency National Priorities grant focused on AMR. This was launched on 1 August, to be led by Lola Olabode, at the WRF. “Our focus is really going to be on filling many of these data gaps, and especially how we can inform risk assessment and move towards policy development that’s effective for combating AMR – and hopefully provide you all in the water sector with the information and tools you need to help the cause.”

More information

The ‘O’Neill Report’ – amr-review.org

UNEP report ‘Bracing for superbugs’ – www.unep.org/resources/superbugs/environmental-action

The Lancet report: ‘Global burden of bacterial antimicrobial resistance in 2019: a systematic analysis’

2022 Environmental Science & Technology paper title: ‘Demonstrating a comprehensive wastewater-based surveillance approach that differentiates globally sourced resistomes’

Nature Communications report title: ‘Selection and horizontal gene transfer underlie microdiversity-level heterogeneity in resistance gene fate during wastewater treatment’

US EPA National Priorities project: ‘Quantifying wastewater sources of antibiotic resistance to aquatic and soil environments and associated health risks’

2022 Microbiome paper ‘Long-read metagenomic sequencing reveals shifts in associations of antibiotic resistance genes with mobile genetic elements from sewage to activated sludge’,

doi.org/10.1186/s40168-021-01216-5

The post Advancing action on AMR appeared first on The Source.

]]>The post Environmental virology and the role of particle association appeared first on The Source.

]]>With increasing demand for fresh water, wastewater reuse will be one of the most significant solutions to provide sufficient clean water. However, the presence and persistence of waterborne viruses has long been one of the largest challenges that must be addressed for the safety of non-potable and potable reuse.

In June 2024, California’s State Water Resources Control Board, USA, approved new direct potable reuse regulations, requiring at least a 20-log10 reduction of enteric viruses. These heightened standards underscore the need for more effective virus removal technologies in wastewater reuse.

Environmental engineers, in academia and industry, are now focused on understanding the environmental behaviour of viruses and developing advanced treatment processes to ensure the safety of reclaimed water, thereby meeting these stringent regulatory requirements.

History of environmental virology

The roots of environmental virology originated in the 1930s with the detection of polioviruses in wastewater. By the 1970s, virus testing included downstream applications (removal by treatment prior to discharges), as well as upstream public health uses, to understand the epidemiology of infectious diseases in the community. During the COVID-19 pandemic, the field of environmental virology expanded significantly, with the rapid adoption of wastewater-based environmental surveillance (WBES) providing crucial early evidence of viral spread.

Advancing knowledge

The scope of WBES has now broadened beyond SARS-CoV-2 to include enteric viruses, other respiratory viruses, and even arboviruses, offering valuable insights into the epidemiology of viral diseases and guiding public health strategies.

Significant advancements in environmental virology methodologies are directly linked to the rapid expansion of WBES, not only for concentration and extraction methods, but also the use of the digital polymerase chain reaction (dPCR) and high-throughput sequencing to quantify and analyse the viral community in wastewater. These methods have advanced knowledge of virus types and concentrations in wastewater that will also influence reuse applications.

Assessing risk to human health

While molecular techniques are revolutionising virus monitoring, the assessment of infectivity is still important, particularly if the goal is virus inactivation rather than complete elimination. Culturing viruses for their infectivity offers a more accurate assessment of the potential human health risks posed by these pathogens, unlike the polymerase chain reaction (PCR), which only quantifies viral genomes.

Researchers at the University of Arizona have successfully cultured infectious adenoviruses in reuse treatment chains in large volumes through serial passages. This allows the assessment of up to 10-log10 removals. While many important waterborne viruses, such as human noroviruses, remain difficult to culture, new model systems such as enteroids, zebrafish and immortalised human salivary cells have been employed and successfully used to propagate human noroviruses (Hayashi et al., 2024).

Industrial practitioners have also conducted field studies to assess the efficacy of wastewater treatment processes in mitigating health risks from waterborne viruses. A team from H2O Molecular carried out a year-long sampling campaign across nine wastewater treatment plants, analysing bacteriophages as indicators of human viruses (Worley-Morse et al., 2019).

Their findings suggest that facilities employing biological nutrient removal (BNR), tertiary treatment, and UV or ozone disinfection demonstrated superior performance in removing human viral indicators. BNR secondary processes typically achieved greater than 2-log10 removal of viral indicators, and BNR plus UV and BNR plus ozone were able to reach more than 4- and 5-log10 reduction of the viral indicators respectively.

Virus persistence

The aggregative state of viruses can affect their persistence in wastewater. Viruses were initially believed to exist as free, independent particles during transmission and infection. However, in complex environments such as wastewater, viruses rarely act alone. Instead, they tend to clump together to form aggregates or attach to other substances present in the water. Viruses can, for example, latch onto particles such as organic matter, bacteria, and other impurities found in wastewater, forming what we call particle-associated viruses.

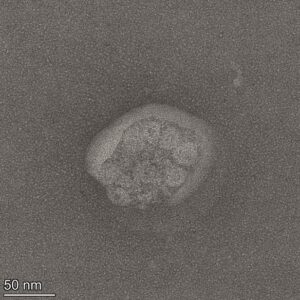

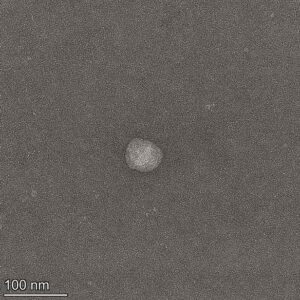

The degree of the aggregative state of viruses also depends on water chemistry and treatment processes. Recent discoveries have shown that some viruses can use the host cell’s secretion pathways to exit the cell in protective extracellular vesicles. These particle-associated viruses are known as vesicle-cloaked virus clusters, or referred to as viral vesicles, where multiple virus particles are enclosed in a fluid-filled sac made of a lipid membrane (see Figure 1).

Figure 1

The discovery of particle-associated viruses enhances our understanding of viral behaviour in wastewater environments, as these viruses can be more persistent during treatment processes and may pose increased risks to human health (Zhang et al., 2021 and 2022).

Tiong Gim Aw analysed particle-associated viruses in secondary effluents collected from five wastewater treatment plants across the USA by using particle-size fractionation through a series of membrane filtration. Many enteric viruses were found to associate with particles, as well as viral indicators such as CrAssphage and pepper mild mottle virus.

What is particularly interesting is that the abundance of a specific virus in a specific fraction of particles with defined sizes is different. For example, adenoviruses were evenly associated with particles across a broad range of sizes of 0.45-100µm, and they were also prevalent in the filtrate (< 0.45µm). In contrast, human noroviruses and enteroviruses were reluctant to bind to particles and were most abundant in the filtrate (< 0.45µm).

Yun Shen conducted the environmental surveillance of vesicle-cloaked virus clusters in wastewater. She identified human norovirus vesicles in both municipal and hospital wastewater and, surprisingly, these viral vesicles contributed to 17-45% of total human noroviruses. Metagenomic sequencing (analysing genetic material from environmental samples) of the vesicles elucidated that many common human enteric viruses were associated with vesicles, including norovirus, rotavirus, astrovirus, and Sapporo virus.

Industrial practitioners also found that particle-association promoted the persistence of viruses in wastewater. A team from Trussell Technologies characterised free chlorine disinfection of bacteriophage MS2, a human virus indicator, in recycled water at a pilot-scale study. MS2 showed a biphasic inactivation profile, exhibiting rapid disinfection kinetics at lower free chlorine CT values, followed by significantly slower disinfection kinetics at higher free chlorine CT values. The particle-association of viruses, as indicated by the turbidity of recycled water, contributed to the reduction in disinfection effectiveness.

Conclusions and recommendations

Environmental virology has made steady progress over the years, particularly driven by methodological advancements. The effective treatment of viruses is critical to meet the stringent safety standards for direct potable water reuse. Assessing viral infectivity through culturing and understanding virus aggregative states and removal throughout wastewater treatment processes are essential. Particle-associated viruses, including vesicle-cloaked virus clusters, exhibit increased persistence during treatment, but not all viruses associate with particles or vesicles in the same way.

Critical questions must be addressed to ensure the future safety of water reuse. The authors offer recommendations from both research and practice perspectives to guide future advancements in this field. First, we need to further advance methodologies to facilitate tracking of viral removal up to 20-log10. This includes improving sample concentration techniques for viruses in wastewater, as upstream sample processing often affects downstream analytical methods.

Moreover, viruses are not ‘lone wolves’, and complex wastewater environments impact virus behaviour and removal through treatment. The association of viruses with particles and the presence of viral vesicles in wastewater have significant implications on treatment processes and virus enumeration for estimating log10 reduction values. A better understanding of the mechanisms of this association in complex wastewater matrices is warranted. Additionally, we must consider how treatment and detection methods may impact the aggregative state of viruses, as this could influence the accuracy of removal and inactivation assessments.

The authors:

Danmeng Shuai is Professor, Civil and Environmental Engineering, George Washington University, USA; Tiong Gim Aw is Associate Professor, Environmental Health Sciences, Tulane University, USA; Yun Shen is Assistant Professor, Civil and Environmental Engineering, George Washington University, USA; Joan B. Rose is Professor, Homer Nowlin Chair in Water Research, Fisheries and Wildlife, Michigan State University, USA; and John Scott Meschke is Professor, Environmental & Occupational Health Sciences, University of Washington, USA.

More information

- Hayashi, T.; Kobayashi, S.; Hirano, J.; Murakami, K., Human norovirus cultivation systems and their use in antiviral research. Journal of Virology (2024), 98, (4), e01663-23.

- Worley-Morse, T.; Mann, M.; Khunjar, W.; Olabode, L.; Gonzalez, R., Evaluating the fate of bacterial indicators, viral indicators, and viruses in water resource recovery facilities. Water Environment Research (2019), 91, (9), 830-842.

- Zhang, M.; Ghosh, S.; Kumar, M.; Santiana, M.; Bleck, C. K. E.; Chaimongkol, N.; Altan-Bonnet, N.; Shuai, D., Emerging pathogenic unit of vesicle-cloaked murine norovirus clusters is resistant to environmental stresses and UV254 disinfection. Environ. Sci. Technol. (2021), 55, (9), 6197-6205.

- Zhang, M.; Ghosh, S.; Li, M.; Altan-Bonnet, N.; Shuai, D., Vesicle-Cloaked Rotavirus Clusters are Environmentally Persistent and Resistant to Free Chlorine Disinfection. Environmental Science & Technology (2022), 56, (12), 8475-8484.

The post Environmental virology and the role of particle association appeared first on The Source.

]]>The post Focused on the future – Basel Wastewater Treatment Facility expands and modernizes to prepare for the future appeared first on The Source.

]]>The Basel Wastewater Treatment Facility (ARA) has been in operation since 1982. After 40 years, the plant is reaching its limits in terms of age and capacity. In addition, the requirements and stipulations outlined in the water protection act have changed significantly with respect to microcontaminants. As operator of the ARA, ProRheno AG aims to meet these future requirements with the expansion and modernization of the facility. The large-scale project will be carried out with an extensive number of partners, including Endress+Hauser.

ARA Basel treats roughly 86,000 cubic metres of wastewater per day. 40 percent is produced by the households of Basel’s approximately 270,000 residents; the rest is generated by industry and businesses. While the new project plan and operational design takes into account further growth until 2040, the expansion provides additional goals and benefits:

- Reliable adherence to current regulatory threshold values

- Ease-of-implementation in response to strengthening of the water protection act, thus eliminating the need for new modifications

- Improved environmental and water protection

- Increased sustainability

ProRheno AG decided as early as 2008 to retrofit the ARA Basel treatment plant. From the beginning the plan was to implement the project without interrupting the operation of the plant. Large-scale projects like these call for forward-looking planning and the right partners. As is customary with municipal projects, all services and contracts were awarded through a tender offer. A reliable partner for the overall project planning and implementation was found in HOLINGER AG.

The tender offer stipulated that the instrumentation provider also cover installation, commissioning, training and documentation. As a complete provider, Endress+Hauser was awarded the contract. System integration and the step into the digital communications era via PROFINET was carried out in conjunction with Chestonag AG.

“Endress+Hauser has provided a large part of the instrumentation for our plant since 1982. Many factors contributed to the decision to select Endress+Hauser, including openness, regional proximity and reliability. Collaboration with the staff is excellent, even when something doesn’t run quite so smoothly,” comments Roberto Frei, Project Manager, ProRheno AG.

Wastewater treatment

The influent wastewater is pumped up to the level of the sewage work via pumping stations (Archimedean screw pumps). The fill level is monitored with Prosonic FDU91 ultrasonic sensors connected to an FMU90 transmitter in the machine room. ARA Basel utilizes four Archimedean screw pumps according to the amount of wastewater that accumulates. Solids are removed from the sewage in the downstream 3-bar screening system made up of coarse and fine rakes. The water level is measured before and after screening to determine the degree of contamination and to initiate cleaning of the rakes. Each of the six rakes is monitored with two Prosonic FMU40 ultrasonic sensors. There is even an escape hatch for wayward frogs. The solids from the rakes and the grit chamber are collected in troughs and then disposed of or reused. The fill levels in the troughs are monitored by Prosonic FMU41 ultrasonic sensors. Any grease that accumulates in the grease trap is fed to the fresh sludge stack. Additional coarse contaminants are removed in the six downstream primary sedimentation basins. At this point the mechanical treatment of the water is complete.

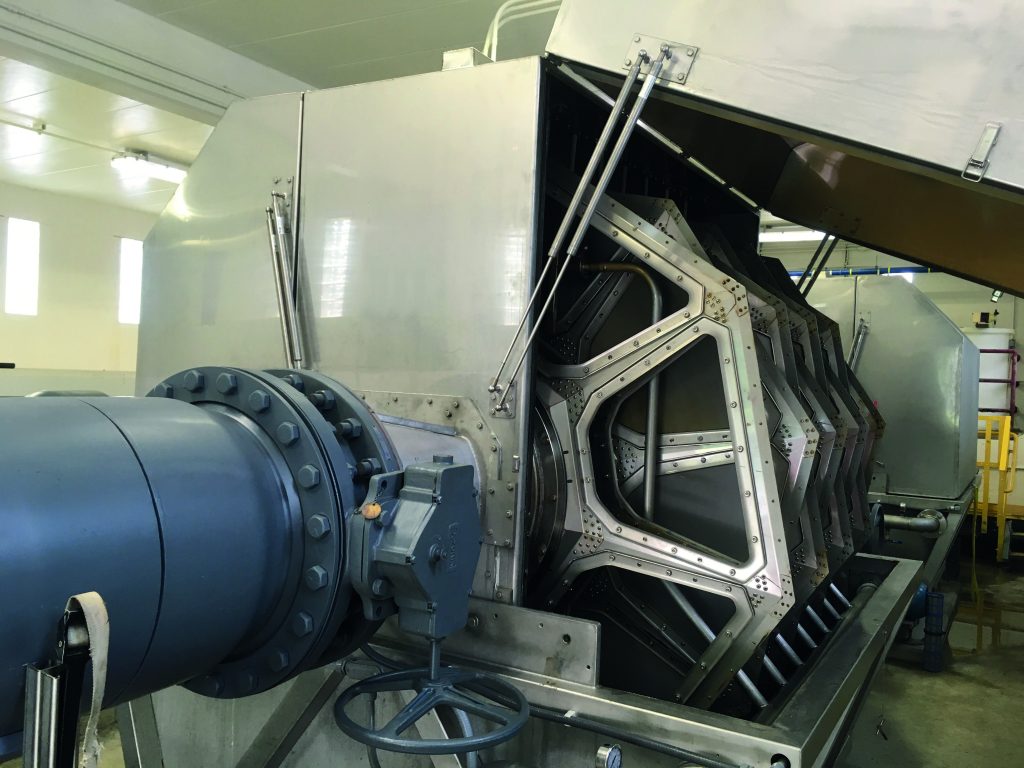

Biological treatment of the wastewater now takes place. ARA Basel decided on the sequence batch reactor (SBR) approach, which offers numerous advantages over conventional methods:

- Variable and compact design that takes up significantly less space

- High-performance, flexible purification

- Closed loop, better resource management

- Independent of influent fluctuations

The wastewater initially flows into one of the two SBR storage basins. From here the wastewater is directed to the nine SB reactors via the SBR pumping station, a process that is measured by Proline Progmag W 400 electromagnetic flowmeters with a nominal diameter of 600. The actual biological treatment occurs in the SB reactors and comprises the following processes: filling, denitrification (agitation), aeration, sedimentation, and decantation. This creates optimal conditions for the microorganisms in the activated sludge so that unwanted substances such as carbon, nitrogen and phosphorus compounds are broken down in the water. To function optimally, the activated sludge needs oxygen, which is forced into the reactors from below. The dosing of the precipitant for all relevant feed points, from the raw water pumping station to the sequence batch reactors, takes place from one central location.

The maneuverable float system, which features an integrated sensor plate, allows the analysis sensors to move around flexibly with the fill level of the sequence batch reactor. The float system is equipped with the following components:

- Oxymax COS61D – digital oxygen sensor with integrated temperature measurement

- Turbimax CUS51D – measurement of undissolved solids and turbidity

- Viomax CAS51D – digital nitrate sensor

- ISEmax CAS40D – digital ammonium sensor (one-off – sporadically used in the respective reactors for a certain amount of time)

The transmitter for the Liquiline CM448 analysis sensors, including PROFINET connectivity for control (PLC) purposes, is located near the edge of the basin, making it easy to access and calibrate. The sensors are automatically cleaned with compressed air. Digital communication via industrial Ethernet enables real-time transmission of value-added data, such as measurement and diagnostic information, directly to the control system. The activated sludge settles to the floor of the reactor at the end of the treatment cycle. The so-called surplus activated sludge is removed at regular intervals. Any floating sludge that forms on the surface is removed and collected in a duct. The fill level of the duct is reliably measured with the Micropilot FRM60 contactless radar-based instrument.

A clear water zone forms in the upper part of the SB reactors, which is fed to storage tanks and then to the next purification stage (microcontaminants) or discharged into the Rhine. Volume flow is measured by Proline Promag W 400 electromagnetic flowmeters with a nominal diameter of 700. As one would expect, the water quality is permanently monitored in order to adhere to the required guidelines.

Implementation of the fourth purification stage

ARA Basel has been successfully experimenting with the removal of microcontaminants such as pharmaceutical residues or microplastics for a number of years already. An innovative and future-proof process was selected for the fourth purification stage: the combination of ozonation and powder activated carbon dosing. This allows ARA Basel, as required by law, to remove 80 percent of the main substances in a reliable and stable manner.

Sludge treatment

All of the accumulated residual sludge (floating, primary and surplus) is currently collected, thickened, dehydrated and fed directly to the facility’s own incineration plant. The energy from the residual sludge is used to facilitate the incineration. The surplus heat has been fed to the city of Basel’s district heating network since 1999 and additionally has been used since 2009 in an energy center to generate cooling water or heating energy for a shopping center air conditioning system and industrial park in the vicinity.

Today there are other and better opportunities for using the residual sludge for energy purposes. The large-scale ARA Basel project will be expanded to include a sludge digestion system that produces digester gas, which is purified, treated and then fed into the municipal natural gas network as biogas – an important step towards increased sustainability.

ARA Basel is well-equipped for the future after completion of the three constructions phases. The following numbers make that more than clear:

- 1,100 tons of nitrogen – 70 percent of the total amount – are removed each year

- 80 percent of the microcontaminants are eliminated

- 90,000 norm cubic meters of exhaust are purified every hour

- Nine SB reactors are in operation, each with a capacity of 12,200 cubic meters

- COD (chemical oxygen demand) load of 62,400 kilograms per day

Do you want to know more on our products, solutions and services for the water & wastewater industry?

Visit us on www.endress.com/water-wastewater

The post Focused on the future – Basel Wastewater Treatment Facility expands and modernizes to prepare for the future appeared first on The Source.

]]>The post VTA unveils cost-saving solution for wastewater plants appeared first on The Source.

]]>Brand new innovation for multiple cost savings

VTA Biolizer® is a synthetically manufactured high-performance product from the R&D department of the VTA Group. It is the result of collected experience over decades from thousands of wastewater treatment plants around the globe. It is manufactured for experts by experts. It solves problems and creates a balance in the biology of the plant. Furthermore, the regulating effect increases operational safety and ensures smooth running and a stable system.

Improved oxygen transfer – for more available energy

VTA Biolizer® equalises the negative properties of surfactants, balances oxygen bubbles, and increases the oxygen contact area between the gas and water phases. The result is improved oxidation properties, resulting in significant cost savings of up to 30% in terms of ventilation energy.

Thanks to its targeted composition, the system product combines surfactant and emulsion cleavage characteristics with good sedimentation and precipitation properties.

Balancing the biology of the plant

VTA Biolizer® helps to break down the emulsified fats and oils in wastewater. Improved settling and thickening behaviour of the sludge leads to a more stable operation. Process optimisation measures can be implemented more effectively, and lead to technical and financial added value for the plant. Plants contaminated by organic chemicals can increase organic breakdown and nitrification – and thus their efficiency – by the dosage of VTA Biolizer®.

State-of-the-art products

VTA Biolizer® is the product of decades of expertise and know-how from the VTA Group. As with all the Group’s self-developed system products, the synthetically produced high-performance product VTA Biolizer® is engineered and manufactured in the labs of the principal site in Austria.Since its founding in 1992, the VTA Group has set standards in environmental engineering worldwide.

Amongst the numerous high-tech solutions from VTA are proven system products for the operational optimisation of wastewater treatment plants, as well as technological innovations and individual plant construction.

Further state of the art products in the Group’s portfolio include a fast-acting precipitant for emergency use in a wastewater treatment plants. This is based on nano-technology, and is called VTA Nanofloc®. In terms of sludge dewatering, the company scores with VTA Biocitran®, an innovative development with selected additives which ensures increased drainability, better floc stability, and a visibly clearer filtrate. For odour control, the method of choice is VTA Calcoferrit®. This product removes odours and prevents the development of new smells. The power solution prevents corrosion and thus reduces maintenance expense for the sewer system. At the same time, it optimises wastewater quality.

In the area of plant construction the Austrian company also offers a wide range of technologies, from underground tanks to dosing systems for polymer.

Want to know more? Drop us a line at vta@vta.ccor visit www.vta.cc/en/

VTA Group, with principal offices in Austria, Germany and Switzerland, is a global player for clean water and the unspoilt environment. The group is currently expanding in the Asian market. It has innovative, sustainable products and technologies for municipal and industrial waste water treatment, deployed in more than 60 countries, and it cooperates with leading international universities. It offers far-reaching environmental protection and provides over 150 million people a day with clean water. The Austrian “Musterbetrieb” (model company) currently holds 68 active patents and represents the German Expert Council for Environmental Technology and Infrastructure (dex) in Austria.

The post VTA unveils cost-saving solution for wastewater plants appeared first on The Source.

]]>The post INVENT iFILT, compact stainless-steel diamond filter: high-tech for tertiary wastewater treatment appeared first on The Source.

]]>INVENT Umwelt- und Verfahrenstechnik AG made use of their long-standing experience in the sector of water and wastewater treatment as well as their expertise in the fields of fluid mechanics, hydraulics and component design to develop the iFILT®-diamond filter. It was constructed especially for the separation of solids from fluids as the next treatment phase after secondary sedimentation. It removes the smallest suspended solids that are still present in wastewater, for example activated sludge flakes, microplastics, precipitation flakes after phosphorus reduction or powdered activated carbon.

It is extraordinarily energy-and-resource-efficient and offers excellent separation performance using a minimum of space.

Industrial enterprises are also greatly interested in the energy-efficient and ecological use of their processing water. The iFILT®-diamond filter can be applied in many areas, such as in the general reuse of processing water in the paper and textile industries, water treatment in fisheries or the treatment of flush water in the beverage industry.

Construction and mode of operation of the iFILT®-diamond filter

The iFILT®-diamond filter consists of one or more filter wheels, backwash unit, enclosure and tray. The filter discs are directly mechanically connected without the additional usage of a central pipe. They are equipped with high-quality, stainless steel, high-performance filter cloth with pore sizes varying between 10 and 100 μm.

The iFILT®-diamond filter is charged directly into the rotor center via a fluid-mechanically optimized distributor, which eliminates the usage of a gasket in the feed area. This rules out any unnoticed leakages and filtrate contamination due to worn-out gaskets. Via the distributor wastewater runs through the filter wheels from the inside towards the outside.

The increasing loads of solids on the filter material slowly leads to a rise of the hydraulic resistance, which eventually leads to a rise of the water level within the filter wheels. When a predetermined water level within the filter wheels has been reached a backwash of the filter cloth is triggered. The periodic backwash or removal of retained solids from the filter cloth is performed with the help of splash water, which is applied to the filter cloth from the outside. The splash water pump is charged with filtrate and thus does not require an external water supply. By way of rotor rotation and cleaning action of the spray nozzles the removed solids are flushed into an internal collecting flume and are drained off the machine separate to the filtrate. The solids are usually reintroduced to the wastewater treatment plant’s influent.

Enhanced hydraulic performance due to cross-flow-filtration

The iFILT®-diamond filter uses a well-thought-out fluid-mechanical overall concept. Depending on the individual case this concept enhances hydraulic performance by up to 100 percent! This is achieved by using a holistic fluid-mechanical optimization approach that is based on the principle of cross-flow-filtration.

The continuous rotation of the disc, the very high rotational speed and the thus initiated effect of a tangential-dynamic filtration limit the built-up of a surface layer to a minimum and enable an optimal hydraulic discharge. A small number of rotating filter discs already achieve high throughputs. This means low spatial requirements: the iFILT®-diamond filter can be put into operation even under restricted circumstances with regard to space.

Many advantages for the operating company

Apart from the hydraulic efficiency and the resulting high economic efficiency the iFILT®-diamond filter offers additional advantages for the operator. The fact that no large-scale gasket neither in the rotor’s feed nor the discharge area is required makes the machine virtually maintenance-free. Leakage and therefore unnoticed deterioration of the filtrate’s quality will not happen. As the filter disc is in constant rotation the energy-intensive backwashing cycles are reduced to a minimum and the overall energy consumption of the filter is extremely low.

All components of the iFILT®-diamond filter are made of high-quality stainless steel, therefore by far exceeding all requirements of modern wastewater treatment with regard to durability and longevity. The applied material meets the highest demands on robustness and mechanical stability even under the most adverse conditions.

Additionally, being an INVENT complete solution, the diamond filter is particularly easy to install. During assembly it will be attached to the supply and drainage pipes and electrically connected – that’s it!

Conclusion

Up to now the processing steps of filtration or micro-sieving have been connected with high investment costs, a fact that has a deterring effect on many municipalities and industrial enterprises. However, public pressure to tackle this subject in order to protect the environment is mounting. The newly developed and fluid-mechanically optimized iFILT®-diamond filter meets all demands on continuative treatment steps in communal and industrial water treatment. INVENT therefore makes sure that tertiary treatment steps can be realized in a more economic and large- scale way.

INVENT Umwelt- und Verfahrenstechnik AG develops, produces and globally sells innovative technical components, systems and processes for the water and wastewater treatment industry.

The post INVENT iFILT, compact stainless-steel diamond filter: high-tech for tertiary wastewater treatment appeared first on The Source.

]]>The post How local wastewater treatment is transforming city infrastructure appeared first on The Source.

]]>By Sandra Postel

Six years into Australia’s Millennium Drought, the managers of an attractive golf club, Pennant Hills in the state of New South Wales, grew anxious. Reservoir levels around Sydney, the state’s capital, had dropped to record lows. To stretch the city’s dwindling supply, Sydney Water tightened restrictions on water use. The club, founded in 1923 and

boasting a championship course, would get no more than 20,000 cubic metres of water per month, well short of the amount it normally used for watering. The club managers pictured

their prized greens turning to ugly browns. But rather than cross their fingers and hope for the best, they took an unusual step: they requested permission to tap into the sewer line

that ran beneath the golf course. The club’s plan was to treat that sewage on-site and then use it to irrigate its 23 hectares of greens.

It might not sound glamorous, but “sewer mining,” as the Aussies call it, is catching on, not just in Australia, but also around the world. As the name implies, it involves tapping into a wastewater collection system and siphoning off some of the sewage that’s moving through the pipes. The sewage then gets treated and used for landscape irrigation, toilet flushing,

and other nonpotable uses.

Many of the world’s dry regions now treat and reuse their wastewater to drought-proof or augment their supplies. In 1968, the Namibian capital, Windhoek, startled the world by

becoming the first city to reclaim its wastewater with advanced treatment processes and then drink it. With annual rainfall of 370 millimetres and no perennial river within 750

kilometres, the city had few options other than to close the loop on its water system. Initially sceptical, the residents of Windhoek have been drinking their reclaimed wastewater for nearly half a century with no outbreaks of disease or negative health effects.

Following Windhoek, most cities add an additional step: instead of drinking their reclaimed wastewater directly, they first send it to an aquifer or surface reservoir to dilute it and allow for some additional natural the costs of building and maintaining treatment plants and piping networks, reduce energy and chemical use, and save drinking-quality water for actual drinking. These savings, in turn, keep more water in rivers, lakes, and streams–which is especially crucial during droughts and summer months, when river flows are low and water demands are high.

“Sydney Water initially couldn’t get its head around the concept (of sewer mining),” says Kurt Dahl, Managing Director of Permeate Partners, the consultancy that helps operate the Pennant Hills system.

The sewer pipe running through the golf course carries wastewater from about 1,000 homes to the coastal town of Manly, some 15 kilometres northeast of Sydney. There the sewage receives only very basic treatment before being dumped into the ocean. So Pennant Hills was tapping wastewater that would otherwise not only go unused but also pollute the South Pacific. As long as the golf club siphoned off its new supply during peak hours of toilet flushing and showering–the morning and evening–it would not interfere with the pressure and flow rate needed to get the remaining sewage to Manly. The little treatment plant sits unobtrusively adjacent to the tenth fairway, surrounded by trees and gardens. It produces virtually no odour.

The sewer-mining scheme has cut Pennant Hills’ potable water use by 92 percent, which earned the club an award from Sydney Water. As a bonus, nitrogen in the sewage is transformed from a harmful pollutant into a valuable nutrient. Pennant Hills has nearly eliminated its use of chemical fertilisers because small amounts of nitrogen get added to the greens each time they are irrigated. Overall the system has proven to be a cost-effective way to drought-proof the links and reduce stresses on Sydney’s water supply. Even the golfers are pleased. “Old-time club members say this is the best the golf course has looked in 30 years,” Dahl says.

What makes sewer mining feasible, and the reason it seems likely to catch

on and spread, are advancements in a variety of treatment technologies over the last decade. At the heart of the Pennant Hills system, which was designed by GE Water, a division of General Electric, is a technology called a membrane bioreactor (MBR). After microorganisms treat the sewage biologically, the resulting product gets drawn through a membrane with microscopic pores that let the partially treated water through but block almost everything else. The waste sludge, which constitutes about 2 percent of the original sewage, then returns to the sewer, while the treated wastewater gets disinfected with chlorine or ultraviolet radiation before being sprinkled onto the gardens and greens.

This MBR process has been in use for several decades, but in recent years both the cost and energy requirements of the membranes have declined substantially. As a result, MBRs produce higherquality water and cost roughly the same as other technologies. MBRs treat more than 3 billion litres of water a day, and installed capacity is growing rapidly.

Dockside Green, a six-hectare mixed-use development in Victoria, British Columbia, and one of the first planned communities to earn Platinum certification for Leadership in Energy

and Environmental Design (LEED), uses an MBR system to treat all of its sewage. The reclaimed water is used to flush toilets, irrigate the landscape, and add flow to a local creek. According to Chris Allen, Regional Manager with General Electric’s Water and Process Technologies division, sewer mining, along with conservation measures, such as dual-flush toilets, water-efficient fixtures, and gray water systems, have reduced indoor water use by 65 percent. Solaire, a 293-unit apartment complex in the Battery Park neighbourhood of New York City, is the first onsite water reclamation system in the US to be built inside a residential apartment building. According to Allen, it recycles about 94,635 litres per day to the building’s cooling towers, toilets, and landscapes.

One of the world’s largest sewer mining projects is at Cauley Creek, a high-end community in Fulton County, Georgia, northeast of Atlanta. As with Sydney’s Pennant Hills Golf

Club, Cauley Creek residents became concerned that drought would lead to restrictions on water withdrawals from the Chattahoochee River, the source of their drinking water. The

community’s MBR system can reclaim roughly 19 million litres of wastewater per day, which gets used by area schools, churches, homes, and a golf course. The on-site treatment and reuse allow more water to remain in the Chattahoochee, a river with an

exceptionally high diversity of fish, mussels, and other aquatic life. In keeping with the community’s rural character, the treatment plant sits quietly inside a classic-looking red barn, complete with a weather vane.

Like Sydney, many coastal cities around the world discharge some or all of their wastewater, treated or not, into the ocean. Shanghai, China’s most populous city, sends wastewater to the Pacific. So does Victoria on Canada’s Vancouver Island. As the

media spotlighted in the run up to the 2016 Summer Olympics, much of the sewage from the 12 million inhabitants of coastal Rio de Janeiro, Brazil, gets dumped into local waters without adequate treatment. US cities and towns collectively discharge 121 billion litres of wastewater every day, a third of which gets treated and released to an ocean or estuary. Each day that’s like throwing away a volume of water equal to 12 times the daily water use of New York City.

Consider Boston, Massachusetts. In the 1980s, when a judge ordered the state capital to stop dumping raw sewage into Boston Harbor, the municipality decided to build a new wastewater treatment facility on Deer Island, a peninsula that extends into the harbour. Today, sewage from 43 greater Boston communities gets transferred to Deer Island, where it gets treated and then sent through a 14.5-kilometre tunnel that discharges into Massachusetts Bay. Once swallowed by the salty sea, the treated water can be of no further service to the state’s communities or freshwater ecosystems.

As water supplies tighten, rivers dry up, wetlands shrink, and persistent droughts lead to water cutbacks, cities and farms are taking a new look at wastewater. It is increasingly viewed not as a nuisance but as an asset. For many activities–from toilet flushing to landscape watering to crop irrigation–water does not need to be clean enough to drink. Matching water’s quality to its intended use opens up a whole new way of thinking about and managing water, one that can turn wastewater from a disposal problem into a valuable new source of supply.

If the whole idea of using wastewater raises eyebrows, it helps to remember that all water on Earth is recycled. Living downstream, one city’s wastewater discharge becomes another’s drinking water supply. About half of the water flowing into the main reservoir for Houston, Texas, called Lake Livingston, is treated wastewater from the Dallas–Fort Worth area. That wastewater flows for about two weeks in the Trinity River, where natural microbial and sun-driven chemical processes boost its quality further before it enters Houston’s reservoir. There it undergoes still more natural cleansing before engineers run it through the city’s water treatment plant to remove remaining impurities. After disinfection it is supplied to Houston residents for drinking, cooking, and other household uses. During dry times, those wastewater flows from Dallas–Fort Worth make up most of the Trinity River’s flow; without them, the river would nearly stop flowing.

More and more, cities are incorporating the reuse of wastewater into their long-term planning. Windhoek and Orange County treat wastewater to such a high quality that it meets drinking water standards. In others, the reclaimed wastewater serves nonpotable uses, such as irrigating lawns, parks, golf courses, and farms; replenishing groundwater; or creating wetland habitat. California, a US leader in the practice, is estimated to reuse 826 million cubic metres of municipal wastewater each year, roughly equal to the water used by 1.4 million households.

Many industries are also turning to reclaimed wastewater as a secure, sustainable supply. Some treat and recycle their own processed water, while others purchase reclaimed wastewater from a local utility. In June 2016, Apple, the maker of computers and mobile phones, announced that it would pay for a new wastewater treatment facility in the central

Oregon town of Prineville and use the reclaimed water to cool its data centres there. By using recycled water, Apple will save Prineville 19 million litres a year.

The post How local wastewater treatment is transforming city infrastructure appeared first on The Source.

]]>The post IWA announce winner of resource recovery from water award appeared first on The Source.

]]>The Saemul Park plant has been constructed underground to ensure greater acceptability with local communities, and allows the surface area above it to be used as a park. The award-winning part of the plant all happens underground. Innovative technologies have allowed the treatment plant to become energy self-sufficient through the production of biogas, while simultaneously recovering water and other valuable resources. The plant has significantly reduced its carbon footprint by reducing greenhouse gas emissions and introduced a ‘Positive Impact Development’ tool to monitor the overall achievement.

“Anyang Saemul Park sewage treatment plant realises three types of resource recovery: water, energy and the climate,” said Kwak Donggeun of POSCO Engineering and Construction, upon receiving the award. “The plant is special because it also includes small water cycle balance for climate recovery through a decentralised rainwater management system. It’s an example of how a sewage treatment plant can be transformed from one where energy is consumed and water lost, to the one that produces energy and collects water as a resource.”

Recovering water and other vital resources like biogas, metals, phosphates and bioplastics from wastewater are critical to deliver a sustainable water sector. The 2017 Award, in partnership with the international knowledge network, WaterShare, is for a proven technology on resource recovery, applied at full or demonstrative scale, which serves as an excellent example for the water sector.

“This award is based on two sets of evaluations, one by academics, the other by practitioners,” said Professor Willy Verstraete, chairman of the judging panel. “A winning solution must be scientifically sound but also able to be scaled up in the real world. That is quite a challenge and, for the successful winner, a great achievement.”

The winning entry receives the award because it represents the best example of a large-scale, economically feasible, and impactful project that uses resources from the water cycle and transfers scientific knowledge.

“By mutually sharing and learning from the experiences of different areas as well as from colleagues from other regions, performance improvement and creative application of innovative solutions will be possible,” said Kees Roest of WaterShare.

The post IWA announce winner of resource recovery from water award appeared first on The Source.

]]>The post Wastewater to help power vehicles appeared first on The Source.

]]>Car company SEAT and Aqualia have joined forces to develop renewable biofuel from wastewater to be used in compressed natural gas (CNG) powered vehicles. To kick off the five-year partnership both companies have begun performing pilot tests in the wastewater treatment plant located in Jerez de la Frontera in the south of Spain.

“With this development and collaboration project with Aqualia, SEAT has become the first brand in the country’s automotive sector to use 100 percent Spanish bio methane obtained from wastewater,” explained Dr Matthias Rabe, Vice-President for R&D, SEAT.

“Fostering the creation of renewable alternative fuels, which help promote future environmental improvements and the long-term use of vehicles in cities are an integral part of SEAT’s CNG strategy.”

SEAT has provided Aqualia with two vehicles to conduct the necessary testing with the bio methane obtained from the wastewater to confirm and verify the entire production chain until the fuel is obtained and used.

According to Félix Parra, General Director, Aqualia, developing the Smart Green Gas project with a medium sized wastewater treatment plant could potentially lead to the daily production of a million litres of biofuel, enough to power more than 300 vehicles.

“This would enable cities to fuel their network of urban buses, bin lorries, police cars or ambulances, among others,” said Parra.

The project, called Smart Green Gas, aims to optimise and make the energy system more flexible to cities that implement this system in their wastewater treatment plants. Parra said this is achieved through the development of new, highly efficient systems for producing biogas and converting it into bio methane, which are generated from sewage in cities’ wastewater treatment plants. The project aims to obtain locally produced, renewable fuel that can be used in the automotive sector or injected into the natural gas distribution network.

The initiative is being developed with the participation of five partners, including Gas Natural Fenosa and Naturgas EDP, as well as public research organisations such as the Catalan Institute for Water Research (ICRA) and the universities of Girona, Valladolid and Santiago de Compostela.

The post Wastewater to help power vehicles appeared first on The Source.

]]>The post Wastewater treatment process uses gravity to cut energy use appeared first on The Source.

]]>“In the UK, the water industry takes up to three percent of total energy used nationally and over 50 percent of that consumption is attributed to wastewater treatment,” Andrew Baird, Technical Director at WPL, told The Source. “Water utilities have been targeted by the Government to significantly reduce power consumption and corresponding greenhouse gas emissions. Improving the energy efficiency of wastewater treatment can significantly cut costs for utilities and industrial processors and has an important environmental benefit.”

By altering the specific gravity, using a higher surface area biomedia and undertaking a hydraulic redesign of the submerged aerated filtration, WPL engineers have ensured that the media now moves slowly, removing the need for scouring. This also enables a reduction in process air as oxygen transfer is improved.

“The key to the new process design is ensuring that the media moves slowly around the tank without the need for energy,” added Baird. “When the media becomes coated with biomass it is naturally heavier so falls to the bottom of the tank where the process air from the diffusers clean off the biomass making the media float. The circulation within the tank prevents sludge build-up both in the tank and on the media. This significantly reduces design parameters and directly reduces energy use,”

This latest research and development initiative is part of a drive to look for ways to improve energy use, which could make it possible for WPL to halve the overall amount of energy used by its plants and bring through-life costs in line with those for rotating biological contactors.

“Over the last three years the company has been looking at the way the media works inside the tank and the way this can be made more efficient,” said Baird. “Implementing this latest research has enabled us to cut the energy taken to run our plants by between 35 and 40 percent, which is a huge benefit for our customers.”

The post Wastewater treatment process uses gravity to cut energy use appeared first on The Source.

]]>