The post Disinfection for bathing water, reuse and stormwater treatment appeared first on The Source.

]]>Hear case studies from major municipalities who manage to secure safe bathing waters, exceed quality requirements for safe and sustainable water reuse, and treat stormwater to mitigate the environmental impact of combined sewer overflows.

Find out more here.

The post Disinfection for bathing water, reuse and stormwater treatment appeared first on The Source.

]]>The post Sustainable water treatment: metal wire mesh for green efficiency appeared first on The Source.

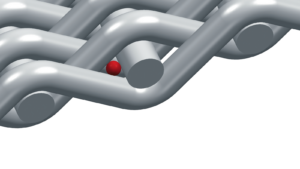

]]>High-performance filtration with metal wire mesh

Filter elements of wire mesh stand out for their reliability even in extreme operating conditions. Offering high flow rates and substantial dirt-holding capacity, they enhance process efficiency, stability and safety. With their ability to filter particles down to a size of 5 µm, including microplastics, they reduce the need for additional chemical treatments – saving energy, lowering operational costs and minimising environmental impact. Their decreased blocking tendency, in comparison to alternative filter media – such as fleece – and their optimised regenerability enable plant operators to extend cleaning intervals and reduce the burden involved in mechanical and chemical cleaning.

Customisability and predictive simulation for optimised solutions

By selecting from various materials, weave types and the suitable support and drainage layers, design and filtration properties can be precisely tailored to a wide range of applications. In addition, innovative 3D mesh structures enable highly corrosion- and temperature-resistant filter meshes with pore sizes smaller than 40 μm.

Advanced simulation tools enable the precise modeling of fluid dynamics and filtration performance before the implementation, ensuring the system meets operational needs without costly trial-and-error adjustments.

Ultra-fine filtration with MINIMESH® S filter mesh

With metal wire mesh, a distinction is made between open square or rectangular meshes and optically closed dutch weave types. In various water treatment systems in which particles down to the micrometre range from 5 μm must be filtered out precisely and economically, the use of MINIMESH® S filter cloths as a filter layer has proven its worth. In plain dutch weaves, the warp or weft wires are woven so close together that they are called zero aperture meshes. In contrast to classic mesh sizes, these meshes have what are known as geometric pore sizes, defined by the diameter of a sphere that can just pass through the filter cloth. Both the geometric pore size and the permeability can be precisely calculated so that the filtration behaviour can be simulated before production.

MINIMESH® RPD HIFLO-S for water treatment

Especially in ultra-fine filtration, innovative 3D filter media also open completely new possibilities: Thanks to their three-dimensional pore geometry, their dirt-holding capacity and flow rate are maintained for significantly longer than with conventional filter media. In addition, special materials can also be woven in the small pore spectrum, making highly corrosion and temperature-resistant filter meshes available in the ultra-fine range for the first time.

Case studies: proven effectiveness across the globe

Haver & Boecker’s MINIMESH® RPD HIFLO-S series has been successfully deployed in a variety of applications, demonstrating its versatility and reliability:

- In Namibia, the jointly funded HygO project is being supported by modern hydrogen technology. The aim is to develop a self-sufficient energy system in the form of so-called microgrids. The HygO microgrid features an additional circuit for biological-mechanical water treatment, in which intermediate MINIMESH® RPD HIFLO 5-S filter cartridges retain particles from 5 µm.

- In Norway, the start-up renasys demonstrates how innovative microscreen systems can significantly reduce the energy consumption of wastewater treatment plants. By using MINIMESH® RPD HIFLO 5-S filters, up to 99% of the dirt particles are removed before the actual clarification process.

- For seawater desalination in drought regions, pre-filtration with MINIMESH® S filter cloths extends the lifespan of reverse osmosis (RO) membranes by capturing fine particles, thereby improving overall system efficiency and cutting operating costs.

Adapting to the future of water management

As water systems evolve to incorporate smarter technologies and more sustainable practices, the role of advanced filtration solutions will only grow. Wire mesh filters align with circular economy principles, offering recyclable materials, reduced chemical usage, and lower energy demands. Their durability minimizes waste, making them a sustainable choice for modern water management. For a deeper dive into the technologies and their applications, download our white paper and explore how Haver & Boecker solutions are shaping the future of water treatment.

As water systems evolve to incorporate smarter technologies and more sustainable practices, the role of advanced filtration solutions will only grow. Wire mesh filters align with circular economy principles, offering recyclable materials, reduced chemical usage, and lower energy demands. Their durability minimizes waste, making them a sustainable choice for modern water management. For a deeper dive into the technologies and their applications, download our white paper and explore how Haver & Boecker solutions are shaping the future of water treatment.

HAVER & BOECKER OHG WIRE WEAVING DIVISION Business Development

Ennigerloher Str. 64 59302 Oelde Germany

Tel.: +49 (0)25 22 30-433 bd@haverboecker.com www.haverboecker.com

The post Sustainable water treatment: metal wire mesh for green efficiency appeared first on The Source.

]]>The post Olympic gold for safe and reliable wastewater disinfection appeared first on The Source.

]]>During the 2024 summer season, from April to September, the effluent from the wastewater treatment plant in Valenton near Paris was disinfected reliably before discharge into the river La Seine, helping to meet the required limits according to the bathing water directive for inland waters. For the first time since the Olympic Games in Paris in the year 1900, Olympic and Paralympic athletes were able to compete in seven different events, such as triathlon and marathon swimming in the river again in 2024.

Find out more here.

The post Olympic gold for safe and reliable wastewater disinfection appeared first on The Source.

]]>The post Phosphorus control in wastewater appeared first on The Source.

]]>Phosphorus has a crucial role in food production and fertilizer manufacturing but in wastewater it is a nuisance, leading to eutrophication of our waterways. Phosphorus removal from wastewater is most efficient when combining the right chemistry expertise with smart technologies.

In this 20-minute on-demand webinar, Kemira experts Jean-Christophe Ades and Jordi Ruiz discuss the regulatory landscape and present customer cases from wastewater treatment plants, who are minimizing their chemical consumption, while meeting strict discharge limits.

Topics discussed:

- How municipal and industrial wastewater treatment operators can

- Optimize chemical dosing and reduce costs

- Future-proof operations in compliance with regulatory requirements

- Maintain reliable process performance and stable effluent quality

- Finally gain peace-of-mind

Watch the video here

The post Phosphorus control in wastewater appeared first on The Source.

]]>The post Shift to Renewable Polymers appeared first on The Source.

]]>Watch this 12-minute on-demand webinar, to learn about pioneering customer cases from Cities who are shifting away from conventional fossil-based polymers, toward renewable solutions.

Topics discussed

How municipal and industrial wastewater treatment operators can:

- Add more renewable materials to the value chain

- Use less fossil feedstocks

- Limit human impact on the planet and make a positive contribution to global circularity and climate goals

Watch the video here

The post Shift to Renewable Polymers appeared first on The Source.

]]>The post Focused on the future – Basel Wastewater Treatment Facility expands and modernizes to prepare for the future appeared first on The Source.

]]>The Basel Wastewater Treatment Facility (ARA) has been in operation since 1982. After 40 years, the plant is reaching its limits in terms of age and capacity. In addition, the requirements and stipulations outlined in the water protection act have changed significantly with respect to microcontaminants. As operator of the ARA, ProRheno AG aims to meet these future requirements with the expansion and modernization of the facility. The large-scale project will be carried out with an extensive number of partners, including Endress+Hauser.

ARA Basel treats roughly 86,000 cubic metres of wastewater per day. 40 percent is produced by the households of Basel’s approximately 270,000 residents; the rest is generated by industry and businesses. While the new project plan and operational design takes into account further growth until 2040, the expansion provides additional goals and benefits:

- Reliable adherence to current regulatory threshold values

- Ease-of-implementation in response to strengthening of the water protection act, thus eliminating the need for new modifications

- Improved environmental and water protection

- Increased sustainability

ProRheno AG decided as early as 2008 to retrofit the ARA Basel treatment plant. From the beginning the plan was to implement the project without interrupting the operation of the plant. Large-scale projects like these call for forward-looking planning and the right partners. As is customary with municipal projects, all services and contracts were awarded through a tender offer. A reliable partner for the overall project planning and implementation was found in HOLINGER AG.

The tender offer stipulated that the instrumentation provider also cover installation, commissioning, training and documentation. As a complete provider, Endress+Hauser was awarded the contract. System integration and the step into the digital communications era via PROFINET was carried out in conjunction with Chestonag AG.

“Endress+Hauser has provided a large part of the instrumentation for our plant since 1982. Many factors contributed to the decision to select Endress+Hauser, including openness, regional proximity and reliability. Collaboration with the staff is excellent, even when something doesn’t run quite so smoothly,” comments Roberto Frei, Project Manager, ProRheno AG.

Wastewater treatment

The influent wastewater is pumped up to the level of the sewage work via pumping stations (Archimedean screw pumps). The fill level is monitored with Prosonic FDU91 ultrasonic sensors connected to an FMU90 transmitter in the machine room. ARA Basel utilizes four Archimedean screw pumps according to the amount of wastewater that accumulates. Solids are removed from the sewage in the downstream 3-bar screening system made up of coarse and fine rakes. The water level is measured before and after screening to determine the degree of contamination and to initiate cleaning of the rakes. Each of the six rakes is monitored with two Prosonic FMU40 ultrasonic sensors. There is even an escape hatch for wayward frogs. The solids from the rakes and the grit chamber are collected in troughs and then disposed of or reused. The fill levels in the troughs are monitored by Prosonic FMU41 ultrasonic sensors. Any grease that accumulates in the grease trap is fed to the fresh sludge stack. Additional coarse contaminants are removed in the six downstream primary sedimentation basins. At this point the mechanical treatment of the water is complete.

Biological treatment of the wastewater now takes place. ARA Basel decided on the sequence batch reactor (SBR) approach, which offers numerous advantages over conventional methods:

- Variable and compact design that takes up significantly less space

- High-performance, flexible purification

- Closed loop, better resource management

- Independent of influent fluctuations

The wastewater initially flows into one of the two SBR storage basins. From here the wastewater is directed to the nine SB reactors via the SBR pumping station, a process that is measured by Proline Progmag W 400 electromagnetic flowmeters with a nominal diameter of 600. The actual biological treatment occurs in the SB reactors and comprises the following processes: filling, denitrification (agitation), aeration, sedimentation, and decantation. This creates optimal conditions for the microorganisms in the activated sludge so that unwanted substances such as carbon, nitrogen and phosphorus compounds are broken down in the water. To function optimally, the activated sludge needs oxygen, which is forced into the reactors from below. The dosing of the precipitant for all relevant feed points, from the raw water pumping station to the sequence batch reactors, takes place from one central location.

The maneuverable float system, which features an integrated sensor plate, allows the analysis sensors to move around flexibly with the fill level of the sequence batch reactor. The float system is equipped with the following components:

- Oxymax COS61D – digital oxygen sensor with integrated temperature measurement

- Turbimax CUS51D – measurement of undissolved solids and turbidity

- Viomax CAS51D – digital nitrate sensor

- ISEmax CAS40D – digital ammonium sensor (one-off – sporadically used in the respective reactors for a certain amount of time)

The transmitter for the Liquiline CM448 analysis sensors, including PROFINET connectivity for control (PLC) purposes, is located near the edge of the basin, making it easy to access and calibrate. The sensors are automatically cleaned with compressed air. Digital communication via industrial Ethernet enables real-time transmission of value-added data, such as measurement and diagnostic information, directly to the control system. The activated sludge settles to the floor of the reactor at the end of the treatment cycle. The so-called surplus activated sludge is removed at regular intervals. Any floating sludge that forms on the surface is removed and collected in a duct. The fill level of the duct is reliably measured with the Micropilot FRM60 contactless radar-based instrument.

A clear water zone forms in the upper part of the SB reactors, which is fed to storage tanks and then to the next purification stage (microcontaminants) or discharged into the Rhine. Volume flow is measured by Proline Promag W 400 electromagnetic flowmeters with a nominal diameter of 700. As one would expect, the water quality is permanently monitored in order to adhere to the required guidelines.

Implementation of the fourth purification stage

ARA Basel has been successfully experimenting with the removal of microcontaminants such as pharmaceutical residues or microplastics for a number of years already. An innovative and future-proof process was selected for the fourth purification stage: the combination of ozonation and powder activated carbon dosing. This allows ARA Basel, as required by law, to remove 80 percent of the main substances in a reliable and stable manner.

Sludge treatment

All of the accumulated residual sludge (floating, primary and surplus) is currently collected, thickened, dehydrated and fed directly to the facility’s own incineration plant. The energy from the residual sludge is used to facilitate the incineration. The surplus heat has been fed to the city of Basel’s district heating network since 1999 and additionally has been used since 2009 in an energy center to generate cooling water or heating energy for a shopping center air conditioning system and industrial park in the vicinity.

Today there are other and better opportunities for using the residual sludge for energy purposes. The large-scale ARA Basel project will be expanded to include a sludge digestion system that produces digester gas, which is purified, treated and then fed into the municipal natural gas network as biogas – an important step towards increased sustainability.

ARA Basel is well-equipped for the future after completion of the three constructions phases. The following numbers make that more than clear:

- 1,100 tons of nitrogen – 70 percent of the total amount – are removed each year

- 80 percent of the microcontaminants are eliminated

- 90,000 norm cubic meters of exhaust are purified every hour

- Nine SB reactors are in operation, each with a capacity of 12,200 cubic meters

- COD (chemical oxygen demand) load of 62,400 kilograms per day

Do you want to know more on our products, solutions and services for the water & wastewater industry?

Visit us on www.endress.com/water-wastewater

The post Focused on the future – Basel Wastewater Treatment Facility expands and modernizes to prepare for the future appeared first on The Source.

]]>The post Award-winning phosphorus recovery appeared first on The Source.

]]>Watch this on-demand webinar, to learn how innovative technology is positively impacting phosphorus recovery performance at a municipal wastewater treatment plant in Germany. If you’re looking to future-proof your phosphorus treatment operations and make the most out of existing resources in a responsible way, listen in.

Topics discussed:

How magnetic phosphorus recovery can generate various treatment process improvements:

- Reliably meet the strictest phosphorus discharge limits

- Reduce sludge volumes

- Increase biogas production volumes and quality

- Reduce electricity consumption in the aeration process

Find out more here

The post Award-winning phosphorus recovery appeared first on The Source.

]]>The post Water Quality Benefits of SIX – a suspended ion exchange system for DOC removal appeared first on The Source.

]]>By Elisabeth Vaudevire

In their adaptation to climate change, many drinking water utilities are facing challenges related to increasing and more persistent dissolved organic matter (DOC) in their surface water sources. The main challenge is often controlling disinfection byproducts (DBPs) after chlorination. Also, the removal of DOC early in the treatment is essential for downstream processes, i.e., membrane and disinfection/oxidation, to perform efficiently and for improved final water quality. While conventional treatment with coagulation can remove hydrophobic DOC and the high molecular fractions of hydrophilic DOC, this process is mainly designed for turbidity removal and requires “enhanced” operation at lower pH to remove higher amounts of DOC.

Strong base anion exchange resins have demonstrated high affinity for DOC, specifically for the low molecular fractions of the hydrophilic DOC which are typically reluctant to removal by coagulation. These fractions of DOC, often referred to as the humic and fulvic acids, are also commonly related to the formation of DBPs in drinking water treatment. Depending on the DOC characteristics in the raw water source, the implementation of ion exchange can beneficially replace or complement coagulation for DOC removal, which improves many water treatment processes. Conventional configurations of ion exchange processes in fixed/ packed beds are limited in use as an early treatment step by the presence of suspended matter and turbidity that causes bed clogging, and these systems are often relegated to later in the treatment train, downstream of filtration.

The Suspended Ion Exchange, or SIX® process, was developed at PWNT (the Netherlands) as a response to this engineering challenge. The process utilizes the strong base anion exchange resin in suspension and in single pass. During operation of the SIX®, a small dose of resin (i.e., 10 to 30 mL/L) is added to the water and kept in suspension while traveling though the contactor ensuring enough contact time. The mixing of the resin ensures the resin to be suspended and provides sufficient energy for very effective contact between the resin and the dissolved organics in the water. After the contact time, the resin is separated from the treated water and collected for immediate regeneration (much like a single pass operation) which helps maintain the fast adsorption kinetics and avoids biofouling on the resin. Finally, to minimize the amount of salt used, the regenerant solution is recycled five times during the regeneration of the resin prior to disposal.

To date, the SIX® process has been implemented at full scale in the Netherlands and in the United Kingdom, in addition to numerous pilot locations across Europe and the USA. The long-term trends using a commercially available resin at these locations have demonstrated DOC removals between 40% and 60% depending on the DOC characteristics, raw water compositions, and process conditions. Using the liquid chromatography – organic carbon detection (LC-OCD) fractionation method, it is clear that the resin preferentially removes humic fractions of the DOC (50 to 80% removal) compared to the non-humic fractions (10 to 30% removal). As a direct result, the UV transmittance of the treated water increased between 10 and 25% percentage points across the locations. A main benefit of applying the SIX® process is its impact on the formation potential of DBPs in chlorinated systems, which studies showed can be reduced by up to 71 % for trihalomethanes (THMs) and 72 % for haloacetic acids (HAA) after SIX® pre-treatment.

Aside from their affinity for DOC, the strong base anion exchange resins used in the SIX® process also interact with the inorganic anions in the water source. Typically, the affinity order is influenced by the concentration and charge density of each anion; and often results in the following preferred adsorption: SO4>DOC>NO3>Cl ≈ HCO3. Whereas the removal of nitrate (typically between 0% and 50%) is often beneficial for the water quality, bicarbonate (0% to 50% removal) and sulphate (up to 80% removal) are usually considered to be scavengers, which requires more chloride exchange and can increase the corrosivity of the treated water. It is, however, possible to mitigate the uptake of inorganic anions by optimizing the resin regeneration. Research on pilot scale also demonstrated the possibility of trading the sodium chloride, which is conventionally used to regenerate the resin, for sodium bicarbonate. This alternative regeneration salt can be used when the chloride level in the treated water is a limiting factor. It also helps reduce the corrosivity of the water and gives more options at some sites for dispose of the waste brine.

The SIX® process conditions are favorable to the longevity of the resin. At one installation, analysis of the resin demonstrated that, after five years of operation in the SIX®, the Lanxess Lewatit S5128 maintained over 90% of its exchange capacity and displayed less than 2% broken beads. After nine years, over 70% of its exchange capacity was maintained and less than 5% of broken beads were observed. In terms of resin losses, design features of the resin separation in the SIX® are key, and thus far, the two full-scale SIX® installations are still operating with their original resin batch.

The suitability of the SIX® process for a particular water source can be demonstrated with a simple jar test. The example below displays the reduction of DOC from a lake water source in time at different resin doses. The measurement of UV transmittance can also be used as a surrogate parameter to DOC for these types of evaluations.

Finally, PWNT is working in collaboration with resin manufacturers towards improving the adsorption capability of the SIX® process to address the current and upcoming challenges for drinking water utilities. For example, much of the research capacity is currently dedicated to the potential removal of PFAS with the SIX® process.

The post Water Quality Benefits of SIX – a suspended ion exchange system for DOC removal appeared first on The Source.

]]>The post Energy-efficient wastewater treatment appeared first on The Source.

]]>The amount of energy consumed in wastewater treatment plants across the world is estimated at 1-3% of global energy output. Modern utilities are consuming between 20 and 45 kWh per population equivalent connected. At the same time there is great untapped potential to generate energy from waste.

If you want to learn how utilities can tackle increasing energy prices, scarcity of resources, and tightening regulations, while maintaining stable and future-proof operations, this is for you!

Find out more here

The post Energy-efficient wastewater treatment appeared first on The Source.

]]>The post Webinar: How to reduce energy consumption in wastewater treatment appeared first on The Source.

]]>In this webinar, you will learn how municipal wastewater treatment plants can use innovative technology to optimize energy-intensive processes, while maintaining stable operations and compliance with tightening regulatory requirements. Kemira´s experts will provide insights on customer cases with significant improvements in energy efficiency, carbon footprint and process stability.

Topics discussed:

• High-impact levers for reduced aeration energy consumption in the biological wastewater treatment process

• Increasing biogas yield through data-driven primary sedimentation

• Optimized chemical dosing with increased product performance

• Maximizing suspended solids feed loads, while improving effluent quality

If you are looking to make your wastewater treatment processes more sustainable without any compromise to performance, this session is for you!

Find our more here

The post Webinar: How to reduce energy consumption in wastewater treatment appeared first on The Source.

]]>