Reuse and recovery are cornerstones of the circular economy. Ana Cardoso, Ana Costa and João Ferreira highlight an innovative project that is taking sludge from a waste product to make a new kind of building material.

Following successful development and implementation, Portuguese drinking water utility guas do Douro e Paiva (AdDP) has established an innovative use for sludge achieved through a process that it is looking to further refine. The utility is responsible for collecting, treating and distributing drinking water to 22 municipalities and, working with its partner BMI CT Cobert Telhas, has established use of sludge as a feed for a building product as part of optimising sludge processing at its main water treatment plant (WTP). The utility is now considering how this approach could be rolled out across its other WTPs and sees potential for this approach to be adopted as a sludge solution around the world.

The utility supplies 1.8 million people with drinking water, 24 hours a day, 365 days a year. Its main and most emblematic facility, the Lever Water Treatment Plant (WTP), is considered one of the best of its kind in Europe and is responsible for treating water for more than a million and a half inhabitants – 85% of the population covered by AdDP’s entire system – producing around 100 million m3/year.

Lever WTP employs sophisticated treatment technology, enabling it to produce around 400,000 m3 of water per day, ensuring the supply of safe, sustainable, high quality water.

The waste challenge

Water treatment produces clarification sludge, which if disposed to landfill comes at a high environmental and financial cost. So, AdDP established a project to find a sustainable solution. As a result, the facility’s sludge is now being used as a raw material in the production of roof tiles.

From waste to building material

A research project was developed in collaboration with the Faculty of Engineering of the University of Porto (FEUP), the Technological Center for Ceramics and Glass, and partner company BMI CT Cobert Telhas. The project studied various alternatives with the aim of preventing the sludge produced at Lever WTP being disposed to landfill.

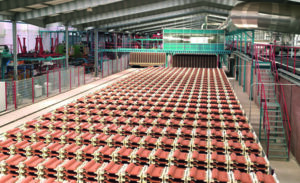

Industrial-scale tests were conducted, along with analysis of the impact of the gas emissions produced from the process of incorporating sludge into raw building materials. It was concluded that the incorporation of sludge into brick manufacturing and, later, CE-marked tiles was feasible.

The scale of the process

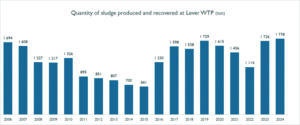

In one of the stages of the Lever WTP, flotation and filtration occur in CoCoDAFF (Counter Current Dissolved Air Flotation and Filtration) units, where filter backwash water and surface-collected sludge are sent to the sludge treatment unit. There, they are dehydrated and processed by thickening and centrifugation. With an annual average of 1500 tons of dehydrated sludge, with 85% humidity, this sludge represents 77% of the total waste produced by AdDP.

Now, 100% of this sludge is recovered for the production of roof tiles, in an innovative operation that demonstrates that sludge need not be treated as an expensive waste product to be disposed of, but rather a resource that can be recovered as a sustainable material for use in the building sector. In 2006, water clarification sludge from Lever WTP ceased to be waste. To date, around 25,000 tons of sludge have been recovered, which has resulted in a total saving of around €1.25m of landfill disposal costs.

Currently, around 15 million roof tiles are manufactured each year using AdDP’s water treatment sludge, with nearly 1800 tons of sludge producing 14 million roof tiles in 2024.

Production challenges

Sludge production can vary according to the characteristics and volume of the water being treated. However, constant procedural adjustments ensure that the characteristics of the sludge do not vary significantly, with one of the most important parameters being humidity.

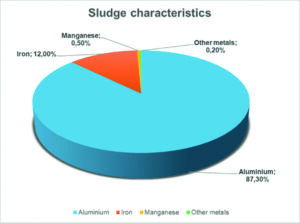

On average, the sludge produced at Lever WTP has the following characteristics:

- 85% humidity

- Organic fraction of about 26% of the dry sludge

- Metals – the high concentration of aluminium is the result of the use of an aluminium-based coagulant. This is a positive outcome, indicating that through this process the aluminium is being retained in the sludge rather than being present in the treated water.

Environmental benefits

When sludge is disposed to landfill, aluminium can leach into watercourses, resulting in contamination if not treated. With the valorisation of the sludge, the aluminium becomes incorporated into the material of the tiles, making it impossible for it to transfer to the environment.

Circular economy approach

Aligned with the 2030 Agenda for Sustainable Development, this pioneering project provides an innovative example of the circular economy and environmental sustainability that can be applied in a wider context. Yet, to date, AdDP is not aware of a similar project in Europe or the world.

Nationwide, thousands of tons of sludge are produced in Portuguese WTPs and sent for landfill disposal. This project highlights how AdDP has found an environmentally favourable alternative for the sludge produced at its largest WTP.

This pioneering eco-innovation project contributes to Portugal’s national circular economy strategy and has proven to be sustainable, fostering synergies between companies from diverse sectors in the use and recovery of waste.

The key achievements of this project are:

- The elimination of the environmental impacts associated with sending sludge to landfill

- Valorisation of the company’s main waste stream

- Increased circularity by incorporating waste as a raw material for a ceramic product

- Financial savings in terms of waste management. Currently, around €70,000 per year is invested in maintaining the project.

The production of roof tiles from water clarification sludge reflects AdDP’s commitment to the circular economy and to minimising and recovering waste from its activities.

The project has increased circularity in the water sector in Portugal, has proven to be sustainable over the years, and has created a success story in the circular economy that has great potential to scale up.

Today, AdDP continues to incorporate all of the sludge produced at Lever WTP into the production of ceramics. To develop this project further, AdDP maintains its partnership with BMI CT Cobert Telhas, to support the environmental and economic interests of both parties in this project. The synergy between the two companies has resulted in a continuous search for process improvements to drive the efficiency of the product.

Project recognition

In 2022, this project was highlighted in the first report of the Sustainable Development Goals (SDG) Observatory as a national example of good practice with regards to the targets set in SDG 12 to ‘Ensure sustainable consumption and production patterns’.

As a project that can be replicated in other countries in Europe and around the world, this innovation serves as an inspiration to all nations that want to take preventative action against environmental impacts. Such adoption of environmentally responsible practices gives rise to renewed hope for the future, promoting the transformation towards a sustainable economy and ensuring a better quality of life for generations to come.

In 2024, this project was the National Winner of the European Enterprise Promotion Awards (EEPA) in the category of ‘Supporting the Sustainable Transition’ and represented Portugal in the final contest in Budapest, Hungary. The project was also presented at the COP29 Summit held in Baku, Azerbaijan.

At a time when environmental concerns have increased globally, this project has made an important contribution to the environment and climate. Therefore, and due to its extraordinary environmental and economic impact at national level, the project has received continuous recognition from the media, with its story being widely disseminated.

Following the successful development and implementation of this project, AdDP has achieved a sustainable destination for its sludge, which it is looking to further optimise by working with its partners in the ceramics industry. It continues to optimise sludge production by investigating new dewatering processes and is considering using a similar approach at other WTPs. This is a project that has the potential to be replicated at other similar facilities around the world and proves that the challenge of taking sludge from a waste product to a valuable asset is achievable.

The authors:

Ana Cardoso is area manager, Ana Costa is Lever WTP production manager, and João Ferreira is production coordinator at AdDP, Portugal