Increasingly, water utilities are developing new methods to utilise the sludge produced from their treatment processes. Yun He, Rongbing Zhang, Kuixiao Li and Jiawei Wang describe a method for producing polyhydroxyalkanoate bioplastic from activated sludge.

In recent years, the generation of large amounts of sludge has posed substantial environmental challenges. Enhancing research, applying innovative technologies for sludge treatment and disposal, and promoting the recovery and utilisation of sludge resources have become critical global tasks. Excess sludge is rich in biodegradable substances, such as volatile fatty acids (VFAs), which can be used to produce biogas and generate electricity.

Sustainable material production

Biobased, biodegradable polyhydroxyalkanoate (PHA) polymers can replace petroleum-based materials in packaging applications and the chemical industry. However, industrial-scale PHA production primarily relies on pure culture methods that require refined feedstock and sterile cultivation conditions. These conditions entail high-energy demands that substantially increase production costs.

Producing PHAs from sludge using mixed microbial cultures (MMCs), such as activated sludge, is a promising option for reducing the cost of both PHA polymers and sludge treatment. This approach is advantageous because it uses inexpensive (or even free) substrates, employs simple, non-sterilisable reactors, and requires less process control. Over the past decade, techniques for producing biodegradable PHAs with open MMCs, using waste and residual carbon sources as substrates, have been extensively studied.

Exploring the opportunities

In light of these benefits, the Beijing Drainage Group Co., Ltd (BDG) is exploring the potential of using MMCs to produce PHAs from municipal sludge rich in organic compounds. The treatment scheme for producing PHAs from municipal sludge is a three-step process: (1) sludge hydrolytic acidification, which promotes the conversion of organic compounds in sludge to VFAs using thermally hydrolysed sludge as a substrate; (2) a microbial enrichment unit with enhanced capacity for producing PHAs under selective conditions; (3) maximisation of PHA content in biomass through an accumulation step, where the enriched biomass is fed with VFAs in a fed-batch mode under unbalanced growth conditions. The crude PHA product can be recovered from a PHA-rich mixed culture biomass in the subsequent process.

For municipal sludge recycling, BDG has established a pilot platform for producing PHAs using MMCs, which includes a 500-litre sludge acidification reactor, a 200-litre microbial enrichment reactor, and a 50-litre PHA accumulation reactor.

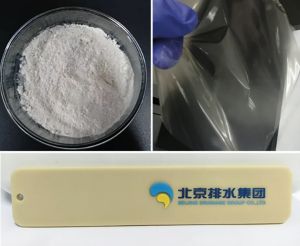

Based on the pilot platform for PHA production from sludge, BDG conducted studies on sludge hydrolysis acidification, enrichment of MMCs with enhanced PHA-producing capacity, and PHA accumulation and extraction, and successfully prepared crude PHA products.

Currently, the degradable organic matter conversion rate in the sludge hydrolysis acidification unit exceeds 80%, and MMCs with superior PHA-producing capacity have been successfully domesticated. A pilot-scale investigation using BDG’s facility has demonstrated that biomass with a PHA content of up to 0.42 gPHA/gVSS can be produced.

Generally, PHA accumulation potential above 0.40 gPHA/gVSS has been identified as a threshold for achieving a promising business case for integrating PHA production into the material flows of wastewater treatment plants.

The extracted crude product has been used to prepare biodegradable plastic film in the laboratory. This has been used to produce plastic bookmarks through an injection molding process.

plastic bookmarks from

PHAs derived from sludge

Findings

Using MMCs to produce PHAs enables the utilisation of wastewater and sludge, transforming traditional wastewater treatment plants into resource recovery facilities. This process effectively converts waste – rich in organic matter and nutrients – into valuable substrates for producing high-quality recycled carbon resources.

The authors: Yun He is an engineer at the R&D Centre of the Beijing Drainage Group (BDG) Co., Ltd., China; Rongbing Zhang is general manager of BDG; Kuixiao Li is deputy director of the R&D Centre at BDG; and Jiawei Wang is director of the R&D Centre at BDG.